What is generative design? Ultimate guide

Generative design is a computer-aided design technique and category of software that uses AI to optimize the design process. Engineers can use generative design software to quickly iterate through many design alternatives and pick the best one according to a set of criteria.

The technique -- sometimes referred to as a design exploration process -- is used in many fields, including architecture, aerospace and construction. It helps engineers in these fields generate more ideas, generate ideas faster and bring products to market more quickly.

Although the term is most commonly applied to engineering and computer-aided design (CAD), generative design can also apply to artwork. Tools such as Dall-E, Midjourney and Stable Diffusion design realistic art from simple text prompts. Generative design is just one variant of generative AI.

How does generative design work?

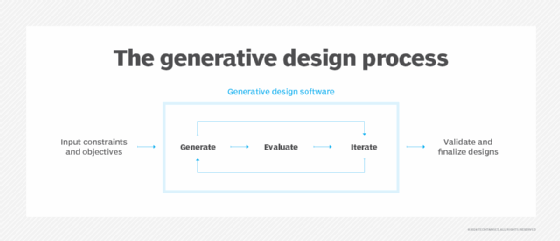

Generative design uses algorithms and AI-powered software tools to generate a quantity of designs based on a set of parameters and constraints. Engineers can use generative design software to create a spectrum of design options based on certain constraints and desired outcomes, then iterate on the designs to meet project requirements. Generative design software uses machine learning in conjunction with user input to improve on previous iterations. It also draws on data provided by cloud computing to inform its designs.

This article is part of

What is GenAI? Generative AI explained

Traditional design begins with a manually created model that a designer uses CAD software to refine. Generative design automatically generates several models from preset constraints. The designer or engineer simply needs to define the problem in terms of parameters, and the software will generate solutions. Generative design occurs in several main steps:

- Define constraints. The designer defines the problem they are trying to solve, determines the basic project constraints and specifies the desired outcomes of the project. Constraints might include material or size limitations. An example outcome might be to improve the efficiency of a given object.

- Refine parameters. Engineers or designers refine broad constraints and goals into data and translate it into software parameters such as spatial requirements, material requirements, cost constraints and performance requirements. This step provides actionable information to start generating different design options. The designer also refines project goals and desired outcomes during this stage.

- Ideation. The software generates several solutions to the problem, aiming to reach the designer's goals according to the specified parameters.

- Analyze and evaluate. The designer or engineer reviews the generated designs and evaluates them based on previously set criteria using simulated tests such as structural dynamics analysis.

- Iteration. After evaluating generated solutions, the engineer chooses designs that meet the project requirements most closely. They can then manually iterate the designs to bring them closer to an ideal solution or iterate by changing parameters or constraints in the generative design tool.

- Validation. After refining the chosen solutions, the designer creates prototypes of the designs to run through real-world tests.

- Production. The designer finalizes the design for production.

In some cases, generative design outputs can mimic the way nature designs systems and structures. This concept is known as biomimicry. It's an example of how generative design can expand the breadth of possibilities for designers by creating novel solutions to design problems.

Generative design use cases and applications

Engineers can use generative design software to do the following:

- Create new part designs.

- Create more efficient parts.

- Create parts more quickly.

- Create parts at a lower cost.

Generative design has a variety of use cases across industries. Some examples include the following:

- Manufacturing. In manufacturing, generative design can be used to find new ways to reduce component weights. It can also be used alongside 3D printing and additive manufacturing -- i.e., the industrial name for 3D printing.

- Automotive. In the automotive industry, generative design can be used to explore new geometries and forms for auto parts.

- Aerospace. In the aerospace industry, generative design can be used to create new aircraft designs with the goals of improved environmental impact, safety and weight reduction.

- Architecture. In architecture, generative design can be used to create more sustainable and resilient buildings, as well as civil feature designs.

- Consumer goods. Everyday consumer products, such as sports equipment, can be designed and manufactured to improve performance and lower cost.

Traditional design tools vs. generative design tools

Traditional design tools and generative design tools have some overlap. Often, generative design capabilities are included as features or plugins in traditional CAD programs.

Tools without generative design functionality -- traditional CAD programs -- require more input from the user than generative design software. The designer must manually adjust parameters and geometry for each design. Generative design tools take a more active role in the design process, creating design options from a set of initial constraints -- such as materials, performance standards and manufacturing methods -- set by the designer.

Based on internet research, here are some examples of computer-aided design offerings with generative capabilities:

- Autodesk Fusion.

- Creo by PTC.

- MSC Apex Generative Design by Hexagon.

- NTop, formerly NTopology.

- NX by Siemens.

What are the benefits of generative design?

The benefits of generative design include the following:

- Simultaneous exploration. Generative design tools can explore many design iterations -- sometimes hundreds of thousands -- at once.

- Mass customization. Generative design tools, in conjunction with Industry 4.0 techniques such as additive manufacturing, enable efficient mass customization of products and parts. It's easier to try a new design or modify specifications.

- Faster design timeline. Generative design automates some of the rote, time-consuming activities involved with ideation and design. Engineers and designers can focus more on continuous improvement and defining problems more specifically.

- More design options. Generative design tools create several model options for engineers to choose from.

- Shallow learning curve. Generative design gives entry-level designers an advantage by enabling them to create something that works from the start. With some previous knowledge of CAD, generative design is relatively easy to learn.

What are the limitations of generative design?

The limitations of generative design include the following:

- Bias. AI algorithms might obscure bias and make it harder to detect.

- Quality. Generative design software can create a large quantity of design options. This can make it more difficult to determine which designs are of acceptable quality and which are not. The software doesn't inherently know the difference.

- Paradox of choice. If the problem isn't well defined, the paradox of choice can make deciding on the right design more difficult. More choices can distract from what is most important to solving a problem. In generative design, many of the designs meet the original criteria laid out by the engineer.

- Guiding the software. The designer still must provide the correct parameters and constraints to the software for its generations to be valuable.

Examples of generative design

Some theoretical example problems that generative design could be applied to include the following:

- Designing a stadium so that it can fit many people and so that everyone has a good view of the event.

- Designing a countertop to minimize the amount of waste in production.

- Designing a more sustainable and resilient building.

- Reducing the weight of an aircraft engine bracket.

- Making an electric wheelchair more portable.

Some real-world example projects that used generative design include the following:

- Moon lander. NASA used Autodesk's generative design software to create a next-generation moon lander. The lander is more lightweight than traditional landers.

- Resource-efficient chair. Philippe Starck designed a production chair using generative design. His goal was to create a chair that used as few materials as possible; the result was the first chair designed by AI.

- Walking car. Hyundai Motor Group designed the Hyundai Elevate, a concept for a car that can walk as well as drive, using generative design.

- Resource-efficient shoe. New Balance used generative design to create an internal lattice of a shoe's outsole with a more organic design.

- New building design. Zaha Hadid Architects used generative design to create the Heydar Aliyev Centre in Azerbaijan. The building resembles a fluid form that emerges from the natural topography of the landscape.

What is the difference between topology optimization and generative design?

The term generative design is often used interchangeably with topology optimization. However, the two concepts are different.

Topology optimization is an older technique that uses a human-designed CAD model to generate a single optimized model for the engineer. The engineer provides specific loads and constraints, and the software generates a model by optimizing material layout according to those requirements.

Generative design does not need a human-generated design to start. The engineer needs only to feed the software a set of constraints, and the generative design software will come up with many possible designs. It automates the ideation component of design.

What is the future of generative design?

Generative design vendors will continue to strive to provide software that aids engineers in their pursuit of new and improved product and component designs. Currently, generative design software is one tool in an engineer's arsenal. Over time, the technology will continue to improve, creating new opportunities and uncovering new obstacles. Generative design will continue to be used to create objects that are more efficient, cost-effective and aesthetically pleasing.

Generative design is just one application of artificial intelligence in manufacturing. Learn the other ways AI can streamline manufacturing processes and increase efficiency.

Editor's note: This article was updated to include a methodology as to how listed products were chosen and to improve the reader experience.