What is SCADA (supervisory control and data acquisition)?

SCADA (supervisory control and data acquisition) is a category of industrial control systems (ICS) that remotely gathers data in real time from industrial processes in order to supervise and control equipment and conditions. SCADA tools enable organizations to control and monitor their industrial devices and make data-driven decisions regarding their industrial processes. SCADA can be used to manage almost any type of industrial process via a graphical user interface (GUI). Both SCADA and ICS fall under the broader category of operational technology (OT).

Components of a SCADA system

SCADA systems gather real-time data to help with the remote management of industrial sites in order to enhance industrial efficiency and output. A SCADA system requires both hardware and software components. The most common hardware devices in a SCADA system include the following:

- Field devices (sensors and actuators). A sensor is a device that detects inputs from industrial processes. It functions like a gauge or meter, displaying the status of a machine. An actuator controls the mechanisms of the various processes. It acts like a switch, dial or control valve to control a device. Both sensors and actuators are controlled and monitored by SCADA field controllers.

- SCADA field controllers. These elements are microcomputers that interface directly with sensors and actuators and send data to the human-machine interface (HMI). They also send control commands to the field devices to which they are attached. Field controllers come in two varieties:

- Remote telemetry units. RTUs, also called remote terminal units or remote telecontrol units, interface with field devices such as sensors, actuators and valves to collect telemetry data and transform it into useful information for human consumption. RTUs are often placed in remote locations, and can be programmed to suit different environmental conditions and applications. They can then initiate specific actions based on specific triggers.

- Programmable logic controllers. A PLC is a small digital computer typically used to control industrial processes based on certain inputs, as well as the standards and instructions provided for a specific process or application. PLCs can monitor and control many types of complex, automated and repeatable processes on a constant basis.

- SCADA supervisory computers. These control all SCADA processes and are used to gather data from field devices. They also send commands to those devices in order to control industrial processes.

- Communication infrastructure. Communication infrastructure enables SCADA supervisory systems to communicate with field devices and field controllers. This infrastructure enables SCADA systems to collect data from field devices and to control those devices.

SCADA software is HMI software. It consolidates and presents data from SCADA field devices, PLCs and RTUs for human consumption. HMI software usually includes a GUI that enables operators to understand, control, analyze and modify the status of SCADA-controlled equipment and processes.

The HMI provides a human-friendly way to interpret data, react to alarms and make data-driven decisions. For example, the SCADA system might send a notification to a user's phone that a device is not working properly. The operator can then decide to stop the device via the HMI. The HMI sends the appropriate command to the PLC or RTU, which then forwards the command to the malfunctioning device and causes it to stop.

Features of SCADA systems

Most SCADA systems include the following features:

- Data acquisition is a foundation of SCADA systems. Sensors collect data and deliver it to field controllers, which, in turn, feed data to SCADA computers. The information is then delivered to an HMI device to support human analysis and decision-making.

- Remote control through the control of field actuators is based on the data acquired from field sensors.

- Networked data communication enables all SCADA functions. Data collected from sensors must be transmitted to SCADA field controllers that communicate with the SCADA supervisory computers. Remote control commands are transmitted back to actuators from the SCADA supervisory computers.

- Data presentation is achieved through HMIs, which represent current and historical data to the operators running the SCADA system.

- Real-time and historical data are both important parts of the SCADA system. Users can use live data for real-time equipment tracking and maintenance, and historical data to track current performance against historical trends and determine what -- if any -- improvements are required.

- Alarms alert SCADA operators to potential problems or significant conditions. Alerts can be configured to notify operators when processes are blocked, when systems fail or when other aspects of SCADA processes must be stopped, started or adjusted.

- Reporting on SCADA system operations can include reports on system status, process performance and reports customized to specific uses.

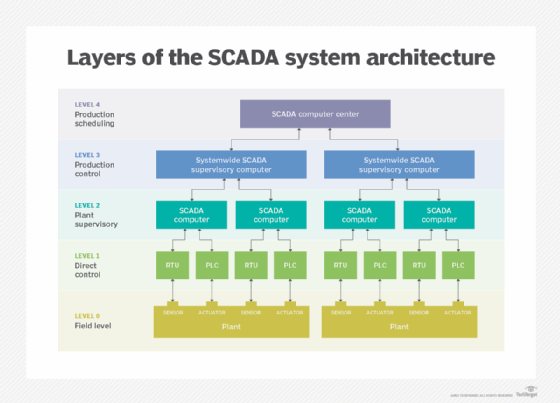

SCADA architecture

SCADA systems operate at five of the six levels defined in the Purdue Enterprise Reference Architecture (PERA), a conceptual model that shows the relationships between OT and information technology (IT):

- Level 0. The field level includes field devices, such as sensors -- used to forward data relating to field processes and actuators used to control processes.

- Level 1. The direct control level includes local controllers, such as PLCs and RTUs, that interface directly with field devices in ways that include accepting data inputs from sensors and sending commands to actuators. Control processors and process-specific microcontrollers are also placed at this level.

- Level 2. The plant supervisory level includes local supervisory systems that aggregate data from level controllers and issue commands for those controllers to carry out. Examples of such systems include alarm servers and process analytic systems.

- Level 3. The production or site-wide supervisory/control level includes systemwide supervisory systems that aggregate data from Level 2 systems to produce ongoing reporting to the production scheduling level, as well as other site or regionwide functions, such as alerts, reporting and HMIs.

- Level 4. The production scheduling level includes business systems and networks used to manage ongoing processes.

- Level 5. The level supporting individual business units and users with systems typically situated in corporate data centers for the likes of servers supporting human resources systems, internal email, CRM, document management, backup, Active directory and security operations.

Why are SCADA systems important?

Many processes in industrial settings -- such as manufacturing, oil and gas, chemicals, transportation, renewable energy, utilities, power distribution, pharmaceuticals, telecommunications and water management -- deal with critical devices and material, and operate in a time-sensitive manner. If even a single device fails or a single process stops working, the entire system can fail, interrupting production. This can result in massive financial losses and cause other problems, such as water or energy shortages and supply chain disruptions.

To prevent such issues, industrial and production facilities must continually monitor, control and analyze all their equipment and processes and proactively address problems before they can escalate. SCADA systems are integral in almost all industrial and production facilities. These systems connect different types of equipment in a plant to provide valuable real-time information about important parameters such as temperature, pressure and speed.

This information enables organizations to better control their industrial processes, find and mitigate errors, prevent downtime and locate opportunities to improve plant efficiency and productivity.

A SCADA system also records and logs all events for reporting. These reports help with predictive maintenance and incident tracking, enabling industrial organizations to predict when a machine might fail and take proactive action to prevent failure and reduce downtime. Additionally, SCADA sounds alarms for potentially hazardous conditions or events -- for example, chemical leaks or overheating -- which provides an early warning system that ensures the safety of personnel and equipment in industrial settings.

Finally, SCADA systems enable industrial automation. By providing precise and automated control of industrial equipment and by automating common routine tasks previously performed by humans, a SCADA system provides better control over large, geographically distributed plants. Automation also eliminates human error, minimizes the potential for environmental disasters and enhances the operability and productivity of production sites.

SCADA use cases and industry examples

SCADA automates and manages many kinds of industrial processes that are too complex or cumbersome for human monitoring and control. SCADA is particularly useful for monitoring and controlling remote processes, where it can help reduce waste and improve overall production efficiency.

SCADA is most commonly used in these industrial settings:

- Electricity generation and distribution.

- Oil and gas refining operations.

- Telecommunications infrastructure.

- Transportation and shipping infrastructure.

- Fabrication and other industrial processing.

- Food and beverage processing.

- Recycling operations.

- Chemical manufacturing.

- Water and waste control.

With the real-time monitoring, remote control and insight generation capabilities of SCADA, these processes can be monitored closely and tweaked to improve performance and output over time.

History and evolution of SCADA

The earliest SCADA systems were implemented in large industrial enterprises as they first started to integrate mainframe computing resources with industrial processes. These systems were monolithic and standalone with little or no networking capabilities. Today, SCADA systems are scalable, interoperable, integration-ready and they support wireless communication technologies to enhance industrial reliability, performance and cost-effectiveness.

As computing, networking, process monitoring and control systems have improved, SCADA evolved through the following four stages:

- First generation: monolithic systems. SCADA systems implemented in the 1960s and 1970s usually incorporated RTUs at industrial sites connected directly to mainframe or minicomputer systems, usually also on-site or connected over wide area networks.

- Second generation: distributed systems. During the 1980s, SCADA systems took advantage of the wide availability of proprietary local area networks and smaller, more powerful computers to enable greater sharing of operational data. However, the lack of open networking standards prevented interoperability across SCADA product vendors.

- Third generation: networked systems. During the 1990s, SCADA systems depended on greater interoperability provided by industry acceptance and incorporation of standard network protocols. These systems could scale more easily, since enterprises could integrate systems across their own industrial infrastructure while using a wider variety of devices and systems.

- Fourth generation: web- or IIoT-based SCADA systems. These systems began appearing in the early 2000s. In this period, SCADA vendors embraced web software development tools to enable transparent interoperability and access via universally available interfaces, such as web browsers running on handheld devices, laptops and desktop computers.

As cloud computing increasingly dominates the enterprise computing world, it changes SCADA systems. Cloud-enabled SCADA systems can scale faster and more easily by allocating cloud computing resources for surges and reducing those resources when demand drops.

Legacy vs. modern SCADA

Many organizations still use legacy SCADA computing resources, such as mainframes, proprietary sensors and actuators. If these systems remain functional, businesses are often reluctant to invest in modern SCADA systems. However, modern systems provide the following benefits over legacy SCADA systems:

- Scalability. Modern SCADA systems are highly scalable and support more hardware devices and software applications than older systems. These systems also often use cloud computing to meet the demands of new industrial workloads.

- Interoperability. Legacy SCADA systems rely on proprietary hardware and software, resulting in vendor lock-in. Modern systems rarely have this problem, meaning organizations can deploy the devices and applications best suited to their specific goals and requirements.

- Communications. Modern SCADA systems support modern communications protocols, which enable greater accessibility to SCADA data and controls.

- Support. Legacy SCADA systems might have limited options for support, while modern systems are more likely to be well-supported by vendors. Use of commercial off-the-shelf hardware, open networking standards and modern software development platforms makes third-party support more accessible as well.

SCADA vs. industrial internet of things

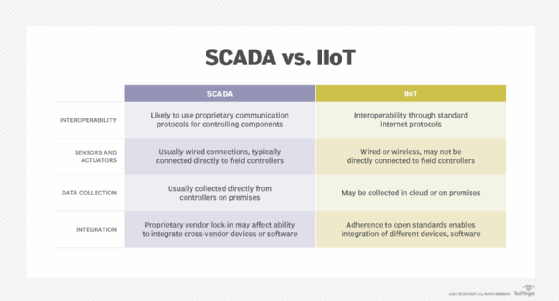

SCADA is sometimes compared with the industrial internet of things (IIoT). Both are used in industrial settings for equipment monitoring and control, so there is considerable overlap between them. However, the two terms refer to quite different things.

A SCADA system collects data from onsite field devices such as sensors and actuators, then processes it on-premises. These devices usually require a wired connection to enable supervisory monitoring and control, although wireless SCADA is becoming increasingly common. The information is then made available to human users via an HMI to facilitate data-driven decision-making, particularly when something goes wrong.

An IIoT platform can collect a diverse range of data from a wider array of devices, including wireless devices. It can also store the data on-site or in the cloud and provide it to users in various formats, such as JSON. Since it can collect more data, it is better suited for predictive maintenance and ideal when organizations must identify opportunities to improve industrial operations.

SCADA systems tend to be monolithic and have limited data capacity and data transformation capability. Scalability and integration can also be a challenge with SCADA since devices made by different manufacturers sometimes do not easily integrate. This is why data and process siloes are a common issue with SCADA, and why SCADA systems cannot achieve a high level of interoperability.

IIoT platforms provide greater interoperability and more options for deploying systems and devices across an organization. They support rich APIs for data transformation and are often based on serverless architecture for easy scalability.

Finally, SCADA systems are typically used to monitor and control specific industrial processes. IIoT platforms have more varied use cases since they don't have as many of the restrictions common to SCADA: limited scalability, complex architectures, performance degradation as the number of users increases, limited data types collected and processed or reliance on HMI for displaying insights.

Both SCADA and IIoT are useful for industrial operations. However, whether an industrial organization implements SCADA or IIoT depends on the system's purpose. SCADA works best for remotely controlling operations and obtaining real-time alerts to problems in specific processes. IIoT is often the better choice for advanced analytics and long-term process optimization.

Unique and common cybersecurity threats and challenges target industrial control systems. Learn about the top ones and how to mitigate them by exploring the top industrial control system cybersecurity threats and challenges.