Nabugu - stock.adobe.com

Learn the 7 types of additive manufacturing

Additive manufacturing is a process in which technology creates 3D shapes by layering materials. Learn how additive manufacturing can support a company's supply chain strategy.

Additive manufacturing is growing in popularity and can help support a company's supply chain strategy. Company leaders should learn the different types of additive manufacturing to determine if any are the right fit for their organization.

Additive manufacturing, also called 3D printing, is the building of objects based on a computer-aided design (CAD) model, adding or layering materials to form shapes. These items may be finished products or parts used to assemble more complex objects. Potential benefits of additive manufacturing include reduced waste compared to other manufacturing approaches and a faster production process for smaller amounts of items.

Learn the seven types of additive manufacturing, as well as how each works.

1. Material jetting

The material jetting method involves a material jetting machine depositing a substance such as photosensitive resin onto a surface.

An ultraviolet (UV) light then cures the material, which enables it to set quickly and facilitates the rapid application of further layers.

A manufacturer can use a drop-on-demand printing technique to control the precise amount of material placed on the surface. This method is mostly used for creating the wax patterns that are used in investment casting.

2. Binder jetting

The binder jetting process involves a blade applying powder material to a surface. Then, a series of nozzles sprays binding agents on the powder to set it in position.

The nozzles then repeat this process, adding more layers to further build the object. Finally, compressed air removes excess powder.

Some common binder jetting materials include ceramics and metals.

3. Vat photopolymerization

Vat photopolymerization involves a build platform being placed in a liquid resin. The platform is steadily lowered, and UV light makes the resin become solid. The repetition of this process creates layers of hardened polymer.

Mirrors focus the UV light and help control the curing process.

Since vat photopolymerization requires liquid to create the items, the manufacturing must include a framework like a vat.

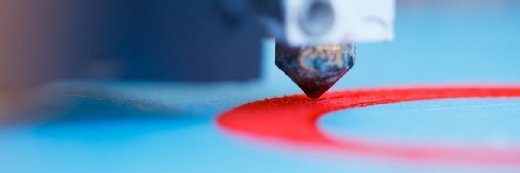

4. Material extrusion

During the material extrusion process, a substance is threaded through a heated nozzle, which results in layers of material. The nozzle can move back over the area as it cools and add more layers to create the finished product.

An item created through the material extrusion process displays noticeable lines, so material extrusion may not be the best option for creating consumer-ready items.

Material extrusion is one of the cheapest additive manufacturing options and is ideal for situations in which the end products or parts do not need to meet exacting standards. Material extrusion is particularly well suited for prototyping.

5. Powder bed fusion

Powder bed fusion involves powder that is stored in a hopper being applied to a print bed by a roller or other tool, which follows the specifications from a CAD model. Next, a laser or electron beam applies heat to the powder, and the powder adheres to the materials underneath it. More powder is then applied, and another application of the beam creates additional layers. The final step removes the excess powder from the finished product.

Powder bed fusion can draw on a wide range of powders, but the most commonly used are plastics, polymers and metals.

6. Sheet lamination

The order of the steps carried out during the sheet lamination process can vary, but sheet lamination involves stretching a substance over another sheet and fusing them together through thermal bonding or another approach. At some point during the process, the materials are cut to meet the manufacturer's specifications using a physical cutter, water jet or a similar tool. More layers are added until the product is finished.

Plastic and fiber are some of the substances commonly used for sheet lamination.

7. Directed energy deposition

Directed energy deposition (DED) involves metal or powder traveling through a nozzle onto a print bed. Thermal power, such as a laser beam, then melts the metal or powder, and the material then cools, fusing onto the layer beneath. As this process repeats, layers form the finished shape.

DED is often used to repair products, but companies can manufacture new items with DED as well.