What is wear leveling?

Wear leveling is a process that is designed to extend the life of solid-state storage devices.

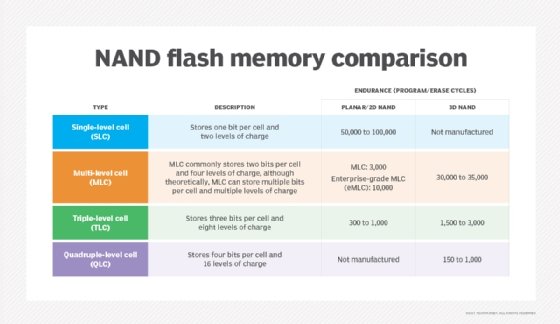

Solid-state storage is made up of microchips that store data in blocks. Each data block can tolerate a finite number of program/erase (P/E) cycles before becoming unreliable. For example, single-level cell (SLC) NAND flash is typically rated at between 50,000 and 100,000 P/E cycles. Wear leveling arranges data so that write/erase cycles are distributed evenly among all the blocks in a device.

Wear leveling is typically managed by the flash controller. It uses a wear leveling algorithm to determine which physical block to use each time data is programmed.

Wear leveling is perhaps even more important in multi-level cell (MLC) NAND flash devices. Where SLC enables a single bit to be written into a memory block, two can be written into MLC blocks at once. This helps bring down the cost of solid-state drives (SSDs), but it increases the wear. To ease that increase in wear rates, enterprise SSDs use enterprise MLC, which slows the write speed, reducing wear rates.

How does wear leveling work?

Wear leveling mechanisms manage how data is written and erased on flash memory. It ensures all memory blocks experience a similar number of write/erase cycles. Flash memory is divided into blocks, each of which can only endure a certain number of writes before it becomes unreliable. Without wear leveling, some blocks might be used frequently while others are rarely touched, leading to uneven wear, early failure of the memory and possible data loss.

Wear leveling uses algorithms to track the number of writes to each block and make decisions about where to store new data. Wear leveling is often accomplished using one of three processes: dynamic wear leveling, static wear leveling or global wear leveling.

Wear leveling's role in NAND flash memory

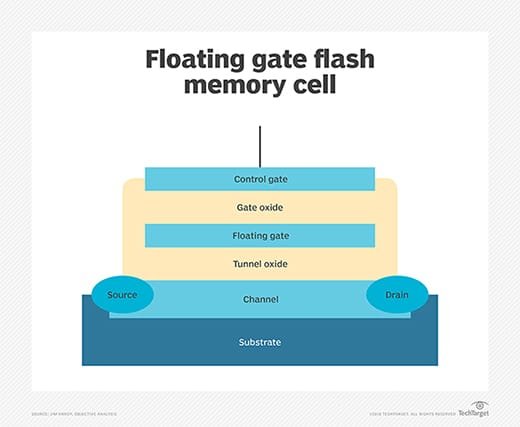

NAND flash memory is the foundation of modern SSDs and plays a significant role in enterprise storage. Wear leveling is critical for the enhancement of longevity and reliability in NAND, which is composed of a series of cells organized into pages and flash blocks. Each cell consists of a control gate, oxide layers, a floating gate, source and drain connections, and a substrate. The floating gate holds an electrical charge and plays a crucial role in storing data. The cells are arranged in a hierarchical structure, with multiple cells forming pages and multiple pages constituting blocks.

The life expectancy of NAND flash memory is limited by the number of write/erase cycles it can endure. Each write/erase cycle slightly damages the oxide layer within the cell, particularly during erase operations, which require a relatively large charge of electrical energy. The endurance of NAND flash varies significantly based on cell density.

Over time, the continuous degradation of the oxide layer can lead to increased bit error rates. This wear-out process, known as NAND flash wear-out, results from the breakdown of the oxide layer within the floating gate transistors. As cells degrade, they can experience P/E errors and read errors, eventually becoming unusable. The wear leveling process addresses these limitations by distributing write/erase cycles evenly across NAND flash memory blocks.

Wear leveling groups

Wear leveling groups, also known as zones, are segments of data within a flash storage device that undergo wear leveling within their respective areas. This approach enables more targeted management of different types of stored data. Examples of groups include system data, user applications and data stored in the boot.

In embedded MultiMediaCards and Universal Flash Storage devices, specific partitions are used for each type of data. For instance, critical data in the Enhanced User Data Area group could be partitioned in an SLC mode for higher reliability, while noncritical data, such as applications or music, could reside in the Non-Enhanced User Area group and be partitioned in triple-level cell (TLC) mode.

Wear leveling groups offer several advantages. They segment data into groups where wear leveling algorithms manage similar types of data, ensuring more efficient distribution of write/erase cycles. Critical data is stored in more reliable partitions, such as those using SLC mode, while less critical data is stored in higher-capacity TLC partitions. By separating data types into groups, the system applies different wear leveling strategies to each group, potentially improving overall performance, quality and longevity.

Dynamic vs. static vs. global wear leveling

The three types of wear leveling techniques -- dynamic, static and global -- work as follows:

- Dynamic wear leveling. This approach pools erased blocks and selects the block with the lowest erasure count for the next write. The downside of dynamic wear leveling is that if a block holds data that isn't accessed, it's never moved to a different block. This limits the number of blocks undergoing wear leveling in an SSD.

- Static wear leveling. This approach operates like dynamic wear leveling, but it also ensures blocks of static data are moved when their block erase count falls below a certain threshold. This additional step of moving data can slow write cycle performance due to overhead on the flash controller. However, static wear leveling is considerably more effective than dynamic wear leveling for extending the life span of SSDs.

- Global wear leveling. This approach works across the entire storage device. It divides it into multiple zones, ensuring write activity is distributed evenly among blocks in the device. If the host computer repeatedly accesses the same zone, global wear leveling intervenes to redirect access to different zones and prevent accelerated wear.

Wear leveling vs. TRIM

The TRIM command set in a computer operating system (OS) instructs a NAND flash device when a memory block is no longer in use and can be erased. TRIM applies to Serial ATA or SATA SSDs. In Serial-Attached SCSI or SAS SSDs, a similar command set is called UNMAP.

Wear leveling, on the other hand, is managed by the flash controller, not the OS. Unlike TRIM, wear leveling only functions when data is being written to the SSD. Wear leveling calls on the flash controller to identify the set of blocks with the lowest P/E cycle counts so that data can be written to them. TRIM activity occurs when the OS has been informed that a memory block is no longer holding data.

Nearly all computer and server OSes support TRIM. The Android mobile OS has supported it since 2013.

Wear leveling vs. garbage collection

Garbage collection is another method of improving the functional life and write performance of an SSD.

Memory cells in an SSD are made up of blocks, and each instance of data is written into each block in a set number of pages. Individual pages can be updated with a new write, but data in a NAND flash cell has to be erased an entire block at a time. This means small data updates waste erase cycles for the unused pages in a block.

During garbage collection, all the pages being written to in a block are moved to a new block, and the unchanged pages in the previous block are erased. This completely frees up the previous block for use in wear leveling.

Wear leveling and USB devices

Wear leveling plays a role in USB flash drives. This process, programmed into flash memory devices, ensures efficient use of memory blocks, maximizing capacity and longevity. The algorithm distributes data evenly across the device, preventing premature block shutdown and nonsequential write errors.

However, not all USB flash drives use wear leveling algorithms due to their smaller flash memory capacity compared with typical SSDs. The absence of wear leveling in some USB drives can lead to inefficient use that compromises reliability and results in a shorter life span.

For industrial applications, it's essential to choose industrial-grade USB flash devices with data protection features that enhance durability and longevity.

Challenges of wear leveling

Wear leveling is an important and often necessary component of extending the life spans of SSDs. However, it can come with certain challenges. Wear leveling can negatively affect performance, especially as the drive fills up. With less free space available, the SSD controller can struggle to manage the wear leveling algorithm effectively. To mitigate this, some manufacturers implement overprovisioning, reserving a percentage of the SSD's capacity for temporary data storage and wear leveling operations.

Implementing wear leveling algorithms introduces some overhead into SSD operations. Static wear leveling, which moves cold data to more worn blocks, incurs additional write operations and can create excessive overhead if not optimized.

Wear leveling is a critical component of maintaining flash memory. Learn the difference between flash and RAM.