TLC flash (triple-level cell flash)

What is TLC flash (triple-level cell flash)?

TLC flash (triple-level cell flash) is a type of NAND flash memory that stores three bits of data per cell. TLC is also known as multi-level cell-3 (MLC-3), 3-bit MLC and X3.

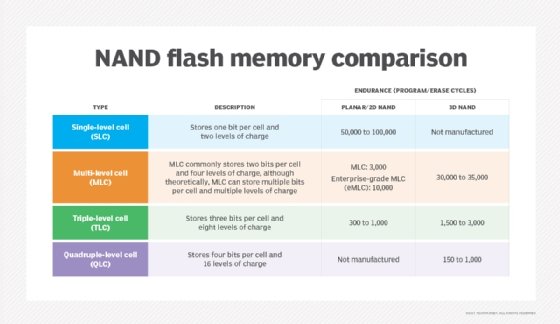

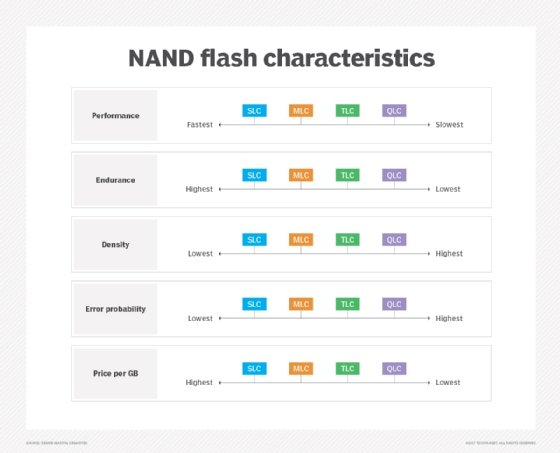

Common use cases for TLC flash include enterprise- and consumer-grade solid-state drives (SSDs), storage cards in digital cameras and mobile phones, and USB drives. TLC flash offers a lower price per gigabyte than single-level cell (SLC) and MLC flash that typically stores two bits of data per cell. However, it's more expensive than quad-level cell (QLC) flash, which stores four bits of data per cell.

NAND flash manufacturers commonly use TLC with 3D NAND flash, in which the memory cells are stacked vertically on the chip. The memory industry moved to 3D NAND flash as manufacturers reached the scaling limits of 2D or planar storage technology, which uses a single layer of memory cells. 3D NAND enables higher storage densities at a lower cost per bit and improves the endurance of the flash. Samsung refers to its 3D NAND as vertical NAND, or V-NAND.

How does TLC NAND flash work?

NAND flash is a type of non-volatile memory that can store a charge for an extended period of time whether or not it's connected to a power supply. NAND flash memory programs write bytes of data to a semiconductor chip only after an electronic charge has erased a unit of data known as a block, which can vary in size.

Each of the three bits of data in a TLC flash cell is either programmed (0) or erased (1). Based on the voltage level, a TLC memory cell has a total of eight possible states: 000, 001, 010, 011, 100, 101, 110 or 111. By contrast, SLC memory has only two states: 0 or 1. And MLC flash has four states: 00, 01, 10 and 11.

Planar or 2D NAND flash typically uses a floating-gate transistor surrounded by an oxide insulation layer to store electrons and change the threshold voltage to program a cell to a 0 or a 1. The program/erase cycle (P/E cycle) eventually erodes the oxide insulation layer, causing manufacturer-set threshold values to become distorted. The problem worsens with TLC over SLC or two-bit MLC planar NAND because there are more values that can shift from the preset threshold points and cause errors.

SSD manufacturers generally use error-correction algorithms, overprovisioning, wear leveling and other mechanisms to improve the endurance, reliability and lower power consumption of planar MLC and TLC NAND flash. These approaches enable use across consumer and enterprise devices and flash storage systems.

Most TLC 3D NAND manufacturers have shifted away from the floating-gate approach to a charge-trap architecture that uses a silicon nitride film to hold the charged electrons. Potential advantages of the charge trap include lower cost and improved endurance and reliability. Because charge trap uses a lower voltage, the chances of defects and charge disturbances are reduced.

Advantages and limitations of TLC vs. SLC and MLC

Two of the main advantages of TLC NAND flash over SLC and MLC are storage density and cost per bit. Because TLC flash stores more bits of information per cell, it can triple the capacity of SLC and offer 1.5 times more storage than two-bit MLC. NAND manufacturers achieve the same capacity with a TLC die as they do with a 32 gigabit MLC die by reducing the die size from 16 billion cells to 10.667 billion cells, enabling cost savings.

Drawbacks of TLC over SLC and MLC flash include performance, reliability and longevity. Its slower performance relates to TLC's eight voltage levels, in contrast to SLC's two levels of charge and MLC's four levels. TLC flash is slower to program data because it requires more time to store the additional voltage levels. The voltage level must be checked and translated back to bits when reading data, and the translation process takes longer for TLC and its eight levels.

TLC NAND has a higher bit error rate than SLC and MLC flash because the small difference between its eight voltage levels makes the read process more sensitive to noise. SLC has only one manufacturer-set threshold value at which a charge is determined to be a 1 or 0, whereas MLC has four and TLC has eight. Values can shift as the flash cell wears out, also leading to errors.

TLC flash has lower write endurance than both SLC and MLC flash. In general, the more bits of data and levels of charge that a planar NAND flash cell has, the fewer P/E cycles, or write cycles, it supports.

SLC flash memory cells can withstand 50,000 to 100,000 P/E cycles before wearing out. A two-bit planar MLC memory cell typically tolerates no more than 3,000 P/E cycles, and enterprise-grade MLC planar NAND has a limit of 10,000 P/E cycles. A planar TLC memory cell generally can sustain no more than 500 or 1,000 write cycles. However, with 3D NAND flash technology, the TLC size is larger, and it can approach the endurance level of planar floating gate-based MLC flash.

With slower performance and lower endurance than SLC and MLC NAND, planar TLC flash originally saw use mostly in consumer devices, such as camera cards and USB drives. But the use of software-based error-correction and wear-leveling techniques enabled its use for read-intensive enterprise workloads. The use of 3D NAND with TLC flash has expanded the enterprise use cases.

Applications for TLC flash memory

TLC NAND flash memory has some limitations compared to other flash memory configurations. However, its price point in terms of performance and endurance makes it desirable for a variety of applications.

Consumer equipment

- Smartphones. TLC flash's cost-effectiveness and performance make it a good choice for smartphones.

- Tablets. The technology provides sufficient storage capacity without impacting user experience.

- Laptops. TLC flash offers a good balance of performance and cost for everyday computing tasks.

- USB flash drives. TLC technology keeps these devices affordable.

Client SSDs

- Base-level SSDs. TLC drives deliver faster storage than traditional hard drives.

- Gaming. TLC flash's increased speed and capacity make it desirable for gaming systems.

Embedded systems and IoT devices

- Embedded memory. Smart home appliances, wearables and industrial equipment can effectively use TLC-based memory.

- Edge computing devices. Specialized internet of things (IoT) devices that have limited storage requirements can make use of TLC NAND.

Tier 2 storage

- Backup and archival storage. TLC is a good choice for storing data that's used infrequently or for disaster recovery storage.

- Occasional-use data storage. Situations where data is read more often than written can benefit from using TLC storage solutions.

Media and entertainment

- Video streaming. TLC NAND can handle video streaming workloads efficiently.

- Digital cameras. TLC-based memory cards in digital cameras are suitable for storage of photos and videos.

Scientific research and VMs

- Scientific computing. TLC SSDs can be helpful for researchers running simulations and data analyses that use large amounts of data and require good performance.

- Virtualization. Virtual machines (VMs) can make use of cost-effective storage with TLC NAND technology.

The future of TLC NAND technology

As TLC technology evolves, its future continues to be strong based on demand for greater storage capacity and access speeds at a reasonable price. TLC's lower power consumption is also helping drive demand. TLC NAND will continue to be used for applications in consumer electronics, automotive and enterprise storage.

Advancements in 3D NAND technology, coupled with TLC storage, will increase storage density. TLC flash offers a good balance among cost, capacity and performance. Continuous improvements in manufacturing processes and TLC functionality should result in more durable and efficient storage and memory technology solutions.

While TLC NAND offers high capacity and cost savings, its performance and endurance -- typically around 3,000 P/E cycles -- are less than other SLC and MLC NAND. This means that proper research and due diligence are needed when deciding which storage technology is appropriate.

When cost per gigabyte is the primary concern and performance and endurance are less of an issue, TLC and QLC will be good choices. Choosing between those two options depends on how write-intensive the workload is; QLC is the better choice for read-only workloads needing reasonable performance.

Learn more about QLC flash and how it can be used in the enterprise.