ag visuell - Fotolia

Prepare for Industry 4.0 challenges on storage, networks

With Industry 4.0 poised to grow across industries, enterprise IT organizations must ask what it will take to support this revolution. Learn how to manage the data-led transformation.

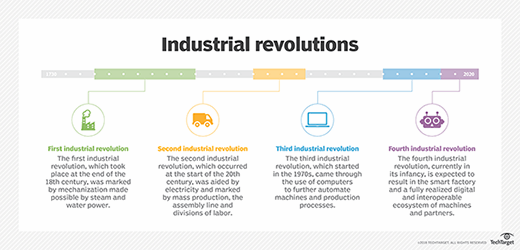

Intermingling cloud, big data, IoT, machine learning and AI, Industry 4.0 presents a combination of elements in a far more interconnected platform than enterprise IT organizations have managed in previous technological eras.

The movement originated and is popular in manufacturing, but many of its concepts apply to other verticals and industries, including IT operations. As a result, enterprise IT teams should prepare for some prominent Industry 4.0 challenges.

IoT and Industry 4.0

Industry 4.0 promises smart factories and other buildings and physical infrastructure, thanks in large part to the internet of things, specifically for industrial usage. In IoT, a massive number of diverse devices are connected to networks. From dumb sensors to fully fledged intelligent edge devices, an organization's overall network-enabled platform sees not only an increase in complexity, but also richer data sets.

Herein lies one of the most significant Industry 4.0 challenges: The effect of IoT on an average enterprise IT organization is not just limited to a few hundred devices that log and send data, but thousands, or even millions that connect to networks and generate data. Many experts think centralization is the best method to deal with IoT data, but the vast majority of it is redundant, which renders a wholesale data storage and processing approach ineffective. For example, a measurement device that states that its calculations are within normal limits creates unnecessary data for the IT organization to store -- it should only collect data if the calculations trend abnormally or exceed set limits.

To manage data volumes associated with Industry 4.0, device makers can build intelligence into the product, enabling it to decide what data is superfluous. Another approach is to interface these data-collection devices with an intelligent edge device, such as a Dell Edge Gateway or a Cisco Integrated Services Router, that aggregates data and analyzes it in situ. An edge gateway is cost-effective and enhances security, as all controlled devices are effectively hidden and airlocked from the main network.

Consider the benefits of a layered plan of attack for data intelligence to combat this challenge with Industry 4.0. IT organizations must architect systems to push data from edge devices and gateways to a concentrated data storage and analysis environment. They can use data management tools, whether they be on premises, such as noSQL database systems Riak and MongoDB, or cloud-based, IoT-specific functional platforms, such as IBM Watson IoT Platform or Google Cloud IoT.

Machine learning and AI

IT teams can thwart another major Industry 4.0 challenge with policy-based operations.

The number of events that happen across a large IoT platform, even after filtration, exceed the management capabilities of any human administrator. Instead, in an Industry 4.0 world, systems work against the backdrop of predefined, required outcomes, and learn and adapt to dynamic situations.

For example, a group of devices runs with a specific set of variables within the maker's limits of operation; however, the devices have a high failure rate. This issue could result from poor quality control from the device maker, or issues caused by the devices' operating variables. An IT administrator identifying the root cause could take too long by the business's standards: While diagnosis processes, the company must either run the susceptible devices and risk failure, or turn them all off and lose a key capability they provide.

Deep analysis, through machine learning (ML) and AI, shows experts how to intelligently tweak the parameters and device setup for variables in operation. The goal is to maintain the organization's overall capability build on the devices, while it swiftly identifies and remediates the root cause of failures.

Combine this approach with widespread device management automation to also diminish security challenges. Organizations can monitor and react to security threats, including zero-day attacks and man-in-the-middle spoofing attempts. Device management automation also gives the IT organization the ability to reprogram a whole process in real time to react to market dynamics that affect the business.

A snag in the revolution

Industry 4.0 requires IT organizations to view everything across the platform as peer systems, and manage them as such. This conceptualization removes separate networks and operations for IoT, data and storage. While each of these elements has its own devices and needs, each must be visible and manageable as a single entity.

Use edge gateways to create a network of cells to hide devices, but confirm that the central intelligence systems understand what exists behind each gateway, and how to securely pass instructions to the devices.

As this change spreads from manufacturing to other industries, IT organizations must prepare for and mitigate Industry 4.0 challenges. Any organization that wants to operate with a building information system, or even to monitor and manage a complex estate of IT systems comprised of servers, PCs, storage and networking equipment, alongside devices ranging from smartphones to printers, must anticipate the data explosion that could otherwise adversely affect the overall IT platform.