Getty Images

Learn difference between additive, subtractive manufacturing

Additive and subtractive manufacturing are two different approaches that are often combined by manufacturers. Learn the difference between the two methods.

Additive and subtractive manufacturing are two different, yet related, approaches to creating parts and finished products. Both types of manufacturing can be quite valuable to companies as part of the supply chain.

While subtractive manufacturing has been in use for decades, additive manufacturing -- better known as 3D printing -- has gained popularity in recent years. Both can benefit manufacturers in multiple ways, including making it easier to create prototypes, and manufacturers often use the two methods together, sometimes combining them on one hybrid machine.

Learn about additive and subtractive manufacturing as well as the differences between each and how to combine them.

Additive manufacturing

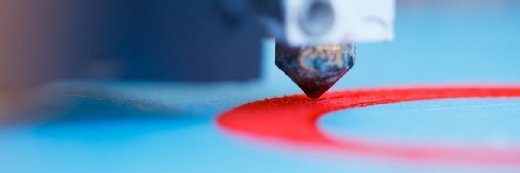

In additive manufacturing, a user composes a model, usually on computer-aided design software, then the software directs a 3D printer or a similar device to make the item, adding materials in thin layers. Polymers and metals are some of the potential materials for additive manufacturing.

Additive manufacturing uses a variety of techniques to create objects, including material jetting, binder jetting, material extrusion and sheet lamination, among others.

Subtractive manufacturing

In subtractive manufacturing, material is cut away from a form such as a block or rod which is usually made out of metal or plastic. Traditional machining or Computer Numerical Control (CNC) machining is used to remove the materials. With CNC machining, software directs the subtractive manufacturing machine to cut away certain material.

Subtractive manufacturing techniques include cutting and grinding and can also carry out the removal through means like water jets and lasers.

When should you use additive or subtractive manufacturing?

Both techniques are frequently used for manufacturing products and parts, and additive manufacturing is especially useful for the following processes:

- short-run and custom manufacturing of parts;

- replicating complicated designs, especially hollow constructions; and

- objects that do not require a clean surface finish.

Additive manufacturing is well-suited for producing a small number of complex objects.

Meanwhile, subtractive manufacturing is mainly implemented for the mass production of standardized parts and products that require multiple surface finishes.

Also, subtractive manufacturing is often more expensive than additive manufacturing.

Combining additive and subtractive manufacturing

Additive and subtractive manufacturing are often combined. For example, manufacturers often use both for the creation of prototypes.

In other cases, additive manufacturing can deal with some of the shortfalls in a subtractive approach, and vice versa. For example, subtractive manufacturing is not good for creating complicated shapes. In these cases, manufacturers can use additive manufacturing to create more complex forms with undercuts and other challenging shapes, then use subtractive manufacturing to add a clean surface finish.