Top 8 ERP implementation best practices

Deploying a new ERP system is a risky endeavor. Learn how to reduce the risk of failure and increase the odds for success with these eight tried-and-true best practices.

When it comes to ERP implementation best practices, the tried-and-true advice stays constant even when things change. And things have changed a lot.

Thanks largely to the rise of modular, cloud-based ERP options, the days of multiyear ERP deployment nightmares are mostly behind us.

"Whether you're an SMB, all the way up to a large enterprise, ERP implementation cycles are one-third [the time] of what they used to be," said Bill McNee, founder and lead analyst at McNee Associates.

What's more, ERP's evolution has not only brought capabilities that were unthinkable just a few years ago, but it has also made ERP attainable for smaller companies that previously were limited to QuickBooks and Microsoft Excel spreadsheets.

Yet, through all this change, many ERP implementation best practices are still used regardless of the size and scale of a modern ERP deployment. None of them, however, guarantees ERP deployment success.

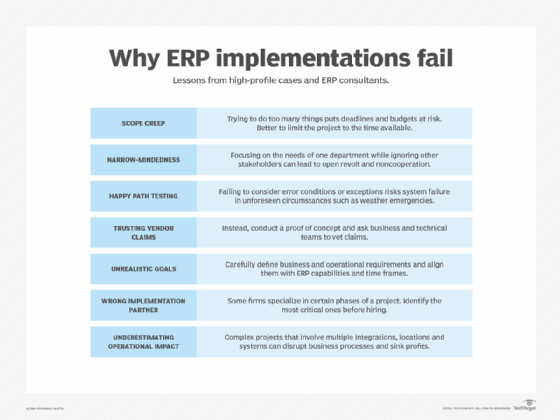

"The risk of failure hasn't really decreased over time; in fact, it's probably increased," said Eric Kimberling, CEO of Third Stage Consulting Group, an ERP implementation firm. "The good news is that the things you can do to mitigate failure haven't changed."

What is an ERP implementation?

The easy answer to such a seemingly simple question is that an ERP implementation is the process of deploying an ERP system. But in truth, the process is complex and involves several distinct stages carried out over many months and sometimes years. It usually starts with establishing a budget and analyzing current software and business processes. Then a project plan is created, a project team assigned, and requirements identified for the new system, which then form the basis for choosing an ERP product to buy. Then the new system is installed, configured and tested, and any data from the old system (if there is one) is migrated to the new. Users are trained, the system goes live, and a smaller team provides ongoing support and maintenance. Then the project manager analyzes the entire project to glean lessons for the next one.

8 ERP implementation best practices

A lot can go wrong with so many steps, systems and people involved. Here are eight ERP implementation best practices to help organizations avoid the pitfalls and increase the odds of a successful ERP deployment.

1. Define business goals first

One of the most important ERP implementation best practices is defining business goals.

Too many companies put the cart before the horse. They choose off-the-shelf software they believe will give them ideas on how to better run their business, Kimberling said.

That approach can undermine the strengths of a business. Instead, they should start by getting clear on desired key performance indicators and doing the strategic planning needed to align the effort with what the company does.

2. Address data quality

The ERP implementation process presents an ideal opportunity to get the entire organization's data in order. Conversely, not addressing data quality can doom the project. Getting a handle on the issue has become even more important during the emerging era of cloud ERP and AI-driven analytics, with data typically being pulled seemingly from everywhere.

"Dirty data can cost you millions and lead to disastrous business decision-making," McNee said. "The key is to commit to rigorous data management practices that help ensure data quality does not get eroded as you aggregate, duplicate and integrate various internal and external data sources."

McNee recommended focusing on the basics before undertaking a data migration effort. That means establishing consistent data definitions and formats and ensuring consistent data practices across systems and organizational boundaries. He also suggests working with a master data management provider that offers comprehensive tools and methodologies.

3. Get clear on your staffing strengths and weaknesses

This is a general IT rule of thumb, but it's especially important for ERP deployments. ERP touches every part of a company, affects nearly every process, records every transaction and spits out insights. If an organization wants to get it right, having the right people can make a huge difference.

One thing to avoid is relying too much on certain individuals. Rick Gemereth, CIO and senior vice president of Lionel, a model train and diecast car maker in Concord, N.C., said it is critical that whoever's in charge is surrounded with talent.

"The person who's leading the project can't save the world on their own," Gemereth said.

Also, make no mistake: An ERP deployment will suck productivity from your organization if you're not careful. That's why it's important to do an honest evaluation of your team and ask hard questions about how much your staff can handle, said Wally Johnson, supply chain director at SMTC Corp., a contract manufacturing services provider based in Melbourne, Fla.

"You might get up and running, but will you be more effective with help from the outside?" Johnson asked.

4. Find a trusted implementation partner

The search for a good implementation partner can be tough, but it's well worth the effort.

"My advice to CIOs would be to make sure you get really good help who's been through the wars of deploying these solutions on a strategic basis," McNee said.

"The secret sauce [for ERP] is figuring out how to apply it to your business," Johnson said. "If you try to do that yourself, you are going to fail."

5. Create a good implementation methodology

Implementation methodologies will make or break the success of an ERP rollout.

A good ERP deployment requires defining business requirements through documentation, Gemereth said. Since Lionel moved to NetSuite's cloud-based ERP in 2010, it has seen what a difference good documentation makes. In fact, the company's attention to documentation has enabled it to customize NetSuite more effectively.

"We've twisted NetSuite in numerous ways, but without documentation, it would have been much more difficult," Gemereth said.

The practice of sandboxing -- running new software in a separate, isolated test environment -- can also be part of good implementation methodology, and Gemereth insists it's critical to the ultimate success of a deployment.

"I don't think it's wise to unplug old systems and plug in new systems and say, 'OK, we're going,'" he said, adding that it is still necessary to run the old and new systems in parallel.

6. Focus on communication

An ERP implementation best practices list wouldn't be complete without a focus on communication.

Communication is especially crucial because ERP deployments are horizontal projects that affect every corner of a company, Gemereth said.

"An ERP rollout is not an IT project," he said. "It's a company project."

Communication is a component of organizational change management, a core best practice that Third Stage Consulting adheres to, Kimberling said.

Regardless of whether a deployment is on premises or in the cloud, employees need to know how the software changes their jobs and then be trained on those new tools, he said. This can go a long way toward determining how effectively users adopt a new system.

7. Embrace the little failures along the way

How can one prevent and embrace failure at the same time? The answer is that there is really no other option. Attempting to prevent ERP implementation failure of the overall project is a no-brainer. No organization wants to spend millions on an ERP deployment only to find the software dead on arrival.

Nevertheless, little failures will undoubtedly happen during the course of a deployment. How an organization responds to them will help to determine how effective the new ERP system ultimately becomes.

But sometimes inevitable failure is staring you right in the face, which leads to the final piece of advice.

8. Know when to wait

Business processes have become so complicated, and the average company has so many more applications and systems it's relying on, that the post-deployment stages of integrating processes and bringing people up to speed have lengthened.

In light of these realities, CIOs should consider patience a best practice, Kimberling said. Sometimes, companies would be better served by resisting the urge to implement a new ERP system now when now may be too soon.

"It may be that processes are broken or people aren't trained that well," Kimberling said. "Tackle that first, wait a few years for these cloud solutions to mature, and you'll be in a better position to leverage technology."

Editor's note: This article was expanded, edited and republished to improve the reader experience.

Tony Kontzer was a California-based freelance journalist who covered technology for more than 20 years.