Gorodenkoff - stock.adobe.com

Industrial metaverse blends real, virtual work environment

In this Q&A, Siemens USA's Barbara Humpton discusses the industrial metaverse and the technologies driving the potential future of manufacturing forward.

Picture a world where manufacturing workers operate their machines not from a factory but from their home via a tablet. Picture a company's supply chain recreated virtually, where testing and analysis occur in real-time.

These are just a couple examples of the industrial metaverse, a work environment where the physical and virtual worlds are seamlessly blended. While it's still in the early stages of development, the industrial metaverse momentum is building.

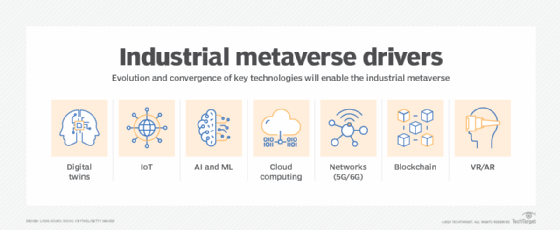

The German-based industrial conglomerate Siemens is one of the main vendors that promises to build and operate the industrial metaverse using technologies such as digital twins, or the digital representation of a physical product or process; industrial software; IoT; and automation.

TechTarget Editorial spoke with Barbara Humpton, president and CEO of Siemens USA, at the Enabling the Industrial Metaverse conference held in June at MIT. Humpton discusses what the industrial metaverse is, some of the technologies needed to build it and how long it will take for it to become real for most companies.

Editor's note: The following has been edited for length and clarity.

What is the industrial metaverse?

Barbara Humpton

Barbara Humpton

Barbara Humpton: Think about all those tools that have transformed the way we game, shop and travel virtually. Now apply all those tools to real problems we have in manufacturing. One of those problems is that you have a fixed number of experts with the machinery that you use in your manufacturing environment. You can't have everyone everywhere at once. Can you use the industrial metaverse to allow engineers, designers and operators to collaborate across vast geographic areas? Yes, you can.

Let's say you want to train employees before they ever get to touch some of your most expensive and complex equipment. You can take them into the industrial metaverse to learn how to do the jobs they're being asked to do.

What are some of the technologies that make up the industrial metaverse? Where does Siemens fit in?

Humpton: You have to think about the sheer cloud computing power for the high-end graphics processing you need for the photorealistic renderings. The metaverse came to the forefront in the science fiction of the gaming world. Now here it is in the technology field. But the comprehensive digital twin is going to cross over the other way. More entertainers and film producers will want to have effects that follow true laws of physics. Siemens is bringing to the table the comprehensive simulation of the natural world, along with computing power, edge computing, cloud computing and AI that will make it possible to build, experiment and get the most out of the metaverse.

What are some examples of manufacturers who are adopting the industrial metaverse?

Humpton: Early adopters are companies that are in the midst of a digital transformation anyway. Or they're bringing a new greenfield operation into being. For example, the Norwegian battery manufacturer Freyr said they want to go to various locations around the world and put in 200 gigawatts of battery production. But they need to know what it's going to take at each location -- what's the right factory size as well as configuration and power needed. They've built a digital twin first of the batteries that they will produce; second, of the production line. Third, they played around with the recycling aspects of this. They've used AI to build robots that will deconstruct used batteries and will be able to recycle 90% of the materials.

They ended up with a battery design with three times performance gains over other batteries. They have a production cycle that takes 90% less time with half the production steps of others. All of that was because they stepped in to the industrial metaverse and used digital twins to do what-if analysis.

How quickly will this transformation happen for most companies?

Humpton: Many are already [adopting the industrial metaverse], but does this mean that the mom-and-pop manufacturer down the street is going to do this? Maybe not instantly, and maybe not all of it. But there are aspects that apply to everybody. This transformation of bringing these digital technologies into manufacturing is quite a different transition than an ERP transition.

In ERP, you're doing open-heart surgery on the entire patient where you must take the old out and put the new in. This is more progressive – first, a cosmetic surgery, followed by procedures that are more comprehensive. But folks can pick the things they want to start with and scale up from there. You can start in almost any corner of the operation.

Are there enough workers prepared to work in the industrial metaverse, or is there a skills gap that needs to be addressed?

Humpton: This also has a spectrum of answers. We will still need Ph.D.'s in engineering because we have to make sure the tools we're building reflect reality. But there are a lot of jobs where the UI can feel more like playing a video game and more intuitive, so operating machines is not something you need an engineering degree to do. There are also progressions of courses to upskill. This should be considered a natural part of lifelong learning now.

What are some of the sustainability advantages of the industrial metaverse?

Humpton: Hands down, it's that you can model before you build. The deal with having to build and experiment is that it's too expensive to change anything, so the idea is to simulate first with a digital twin. It's the adage of measure twice, cut once. Once you start building things in the real world, it gets expensive to make changes, and you're stuck with what you have.

Jim O'Donnell is a senior news writer who covers ERP and other enterprise applications for TechTarget Editorial.