Funtap - stock.adobe.com

Ukraine war, sanctions will extend supply chain disruption

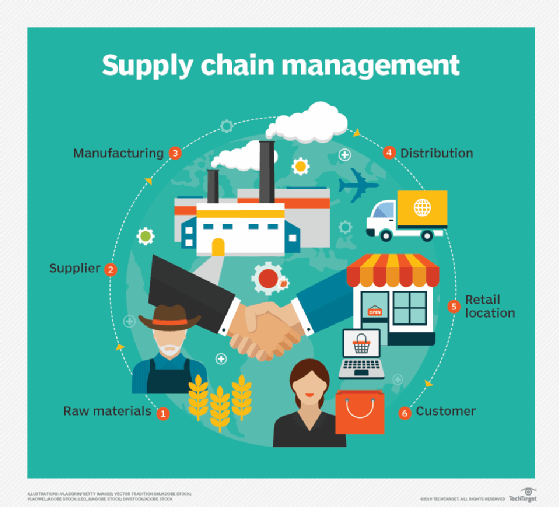

Supply chains have been hit hard in the past two years, and the challenges do not get easier with the Ukraine war, which will affect industries for years to come.

The Russian invasion of Ukraine means that supply chain disruption, which reached new heights due to the COVID-19 pandemic, may take even longer to alleviate.

The war, along with sanctions on companies doing business with Russia, as well as U.S. companies pulling out of Russia, will have longstanding effects on global supply chains and exacerbate global inflation, according to industry experts. But it may also provide opportunities to address supply chain vulnerabilities.

The past two years have been among the most challenging for supply chain professionals because the problems are getting more complex rather than diminishing, said Dana Gardner, president and principal analyst at Interarbor Solutions, an enterprise computing systems consulting firm in Gilford, N.H.

Dana Gardner

Dana Gardner

The Ukraine war has added significantly to that complexity for two main reasons, he said.

"One is that this was unpredictable, and I don't think anyone was forecasting that this level of warfare was going to be happening in Europe," Gardner said. "But there's also the scale. This isn't just a hurricane that hits a 70-mile-wide swath of coastline in North Carolina. This is a global event that's impacting economies -- some much more than others."

On the face of it, taking Russia and Ukraine out of the global economy shouldn't make a huge difference given their relative financial states, but they contribute significantly to areas including energy production, rare earth minerals and wheat. Disruption in these supply chains will be felt for some time, said Simon Ellis, practice director at IDC.

Simon Ellis

Simon Ellis

"Russia and Ukraine combined are only the 10th largest economy in the world, but it takes a while to recalibrate from a supply shock," Ellis said. "We'll see the ripple effect of that for a while, certainly for the duration of this year and maybe into next."

Companies that have not diversified suppliers are courting serious damage, he said.

"Whether it's floods in Thailand in 2011, a tsunami in Japan in 2010, a rolling pandemic or Russia invading Ukraine, we're long past the point now of understanding that there will be impacts on supply chains," Ellis said. "Any company that's still single-sourcing critical components has been remiss."

Wide-ranging supply chain disruption

Sam New, senior principal analyst for supply chain research at Gartner, zeroed in on industries and supply chain repercussions most affected by the Russian invasion.

Sam New

Sam New

The first are materials like rare earth minerals, which will lead to further shortages of semiconductors. The second is wheat, which will affect the world food supply chain, as Ukraine and Russia are significant exporters. The third is petroleum and natural gas production, which will affect costs in transportation and logistics.

"There's also a fear that there may be a Russian-Chinese alliance," New said. "If that happens and China opposes the U.S. sanctions, no one knows how that would affect consumer and producer markets between the U.S. and China, or NATO countries and China."

This uncertainty is worrisome for manufacturers that rely on the semiconductor industry, 70% of which is based in Taiwan, said Mike Jette, telecommunications, media and technology industry lead at GEP Worldwide, a firm in Clark, N.J., that provides supply chain-related software and consulting services.

Mike Jette

Mike Jette

"No one knows if these events will cause China to take a more aggressive stance toward Taiwan," Jette said. "But if you are in an industry that's heavily reliant on semiconductor manufacturing capacity in Taiwan, you've been nervous and you're more nervous now."

The effects of the war and sanctions also extend beyond shortages of raw materials and goods, Jette said. One of the main unknowns is how the crisis will affect workforces in Ukraine and Russia.

"The direct workforce exposure in these countries is relatively small for most manufacturers, but a lot of them have some pretty significant third-party exposure," he said. "If you think about technology firms, they have tended to use a lot of contract talent in their processes, and Ukraine is not an insignificant source of that talent."

Companies that have relied on Ukrainian and Russian talent to staff or augment supply chain software development and hardware engineering teams are scrambling to find out where those people are and how they can manage the uncertainty, Jette continued.

Reputational risk a concern

Complying with sanctions and avoiding environmental, social and governance reputational risk is another thorny issue that affects company-supplier relations, said Jagmeet Lamba, founder and CEO of Certa, a San Francisco-based firm that provides a third-party supplier risk management platform.

Jagmeet Lamba

Jagmeet Lamba

The sanctions applied by the U.S. on Russian-owned financial institutions and companies affect a company's entire supply chain, which creates added complexity due to how interconnected the global economy has become, Lamba said.

"Because ownership structures are so networked nowadays, and the U.S. sanctions laws apply to owners of the companies that you're working with," he said. "So every company, by law, should be not just screening the companies that they work with, but also the entire ownership tree of the companies that they work with."

This is difficult work, but can be made easier with tools such as Certa's automated risk management platform designed to map relationships and company ownership, including across industry verticals, according to Lamba.

"Some companies that are very diligent will go deep, but it's hard to go deep for every single third-party relationship," he said. "In the past, [a supplier] might just be a manufacturing shop, but recently the companies that make the most money are in technology and services, and the ownership could be anyone."

The biggest danger for companies is more reputation than fines, which can be small if companies aren't willfully trying to avoid the sanctions.

"Your clients are certainly going to be very concerned if it's in the news that you did business with anyone tied to [Russian owners], and your [environmental, social and governance] score reduces dramatically," Lamba said. "[You also may lose employees] because they have lost faith in your company if you have any sort of sanctions violations or any association in Russia."

Don't waste a crisis

While the crisis is dire, it's also an opportunity for companies to make changes that address longstanding vulnerabilities in supply chains, New said.

"This is a learning experience, and risk management, building up network resiliency and business continuity management are not just a necessary exercise," New said. "If done properly, they can be a source of competitive advantage for an organization. Instead of a check-the-box exercise, this can be a strategic component in an annual operating plan. And what better way to test and learn than in a real crisis?"

Jette agreed that this is an opportunity to make resilience a core part of how companies design supply chains.

"We need to take the crisis and put it to use. As supply chain professionals, we have overemphasized what we thought were hyperefficient supply chains," Jette said. "We need to redesign with resiliency as one of the principles, not just lowest costs in a perfect world."

Resilience and visibility needed

However, dealing with the crisis will be neither easy nor quick, analysts said.

Companies should look at mitigation as short-term, medium-term and long-term initiatives, New said.

According to New, in the short term, companies need to increase visibility into multitiered supply chains, starting with first-tier suppliers, then moving to second, third and so on. In the medium term, companies should beef up inventory buffer stock and diversify sources from all elements in the supply chain, including direct materials, suppliers, contract manufacturers and logistics providers.

"Long term, you need to take both a tactical and strategic approach to increasing resilience in at-risk, concentrated networks and deploy strategic redundancies that will drive competitiveness and will cascade down," New said.

Going forward, companies that have invested in supply chain visibility and collaboration platforms will do better, Jette said.

"If people can't see your positions and your demand, they tend to hedge and get cautious," he said. "So the disruption will promote an increasing trend for that type of collaboration and integrated value planning and execution software. The folks who have that capability in place are in a better position to reassure their customers and work with those suppliers."

The Ukraine war combined with the other disruptions from the past two years should lead companies to reevaluate long-established supply chain practices such as single sourcing and just-in-time delivery, Interarbor Solutions' Gardner said.

At least some of the response may come with reshoring or nearshoring of critical supply production, like semiconductors, he said. This may not happen on a large scale for a variety of reasons, including high labor costs and lack of skills in those industries, but the high costs of transporting goods from overseas and support from the Biden administration may bring some chip manufacturing back to the U.S.

"You need to think that maybe the goods are more expensive to make in America, but the costs of getting them across the ocean are now so high, that's a whole new calculus," he said. "The changes day to day and week to week are substantial, but it takes years to put into place the physical distribution and physical plants to solve these problems."

Jim O'Donnell is a TechTarget news writer who covers ERP and other enterprise applications for SearchSAP and SearchERP.