Getty Images

Managing supply chain risk requires new priorities, tools

Understanding that cost may not be the top driver in supply chain risk management is critical in the new normal. Learn why and what technologies can help.

Words like supply chain and logistics first became household terms thanks to pandemic-related disruptions. Those disruptions aren't going away, which means organizations need new and better approaches for managing supply chain risk.

That's one of the important messages from Eric Kimberling, CEO of Third Stage Consulting. Supply chain managers should understand that focusing solely on cost is unlikely to help them manage today's disruption risks. Leaders may also need to consider new tools and understand why relying too heavily on specific vendors is a bad idea.

Dangers of key supplier overreliance

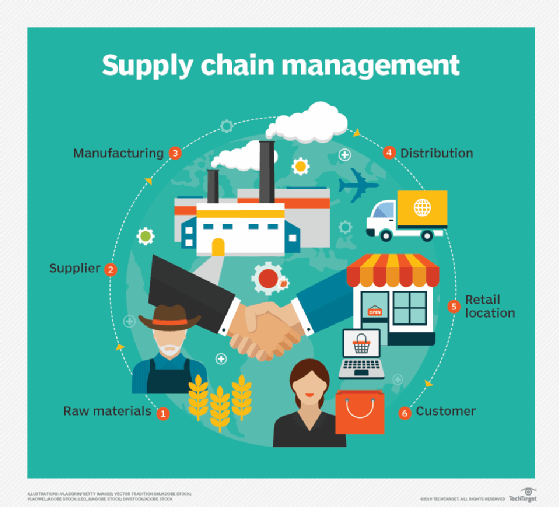

Since supply chain management involves stakeholders across the organization -- operations, finance, sales and so on -- managing it well is incredibly complex. What are some strategies organizations can use to proactively manage potential risk and disruption?

Eric Kimberling: To create a truly resilient supply chain -- one that's flexible and can adapt to whatever changes and curveballs we might get in the future -- we want to look at our processes and understand where the risks are. The pandemic and other events already exposed a lot of these risks. But there are probably existing risks that we haven't seen yet.

So it's a matter of critically looking at the end-to-end supply chain processes, understanding where the bottlenecks are and understanding where you have, for example, too much vendor concentration or too much vendor risk. If you're overly dependent on one vendor for a critical raw material, that's a risk. Are there other vendors out there you should be looking at? What is plan B, plan C, in case vendor A goes out of business, can't fulfill demand or raises their prices unexpectedly?

We want to know that we've got a clearer view of our vendor management, our supplier management, and also a good understanding of who's delivering us the highest quality, best cost and in the most timely fashion. We need to understand, evaluate and measure all the different suppliers throughout the supply chain and analyze those risks.

There are also some other areas you want to examine: For example, what's the geopolitical risk of having a vendor in certain parts of the world?

Prioritizing supply chain risks

Your supply chain might have a number of issues. How do you decide what to prioritize and tackle?

Kimberling: It's important to rethink what your prioritization criteria are. Up until 2020, I would say most supply chain managers were focused on, 'How do we optimize cost?' and 'How do we optimize throughput?' That is the traditional way of thinking about supply chains.

Now you have to add another layer of complexity: What about the long-term sustainability and the overall flexibility for the supply chain? How do we adapt quickly if there's a disruption? We might have to look at higher costs in the name of having more predictable risk mitigation efforts in place. In the past, you would just say, 'Let's look at where the biggest cost savings could be if we were to adapt or adjust something within our supply chain.'

Now, mindsets have shifted about the best approach to supply chain risk management. You have to look at the overall reliability of the supply chain. Today's supply chain risk management is a matter of defining what your key prioritization criteria are and identifying -- based on those criteria -- where the biggest risks are.

Supply chain risk technologies

What supply chain technology can help organizations with their new supply chain management strategies?

Kimberling: You certainly have your traditional tools like back-office ERP, supply chain management systems and warehouse management technologies. These are meant to automate and provide visibility and data to help you understand strengths and weaknesses in the supply chain. Those technologies are still important, and companies are still getting advantages from them. But what we found is that traditional back-office ERP and supply chain management systems aren't necessarily cut out for what organizations need today.

Now there are tools that augment traditional ERP and supply chain management systems to help you identify potential risks. You also have the use of artificial intelligence in a lot of the emerging supply chain tools that will help identify and predictively assess where there might be potential problems, or where there's too heavy of a concentration of risk, or where some sort of geopolitical issue might be affecting a subset of your supply chain.

What are some examples of these supply chain tools or ways to research what might be best for an organization?

Kimberling: One thing to start with is to look at the available supply chain-focused systems. So, for example, look at systems like JTA, Blue Yonder, Manhattan Associates and Infor Nexus. There are a lot of these niche solutions that focus exclusively on supply chain management and optimizing the supply chain. Some of those use emerging technologies like AI.

In addition, there are newer tools like Craft.co. They make a tool that's meant to help identify where the supply chain risks are. It basically consolidates third-party data about geopolitical issues and things that could be affecting your supply chain, and it helps you identify where the pockets of risk might be. It's a good way to augment your core supply chain and ERP systems.

Those are just a few examples. The key takeaway would be: Really think outside the box of your traditional ERP off-the-shelf, back-office system. And look to other point technologies to really help you optimize your supply chain and mitigate that risk.

About the author

Diann Daniel is a senior site editor in TechTarget's Enterprise Software and Services media group. She oversees SearchCIO, SearchHRSoftware, SearchERP and SearchSAP.