warehouse management system (WMS)

What is a warehouse management system?

A warehouse management system (WMS) consists of software and processes that allow organizations to control and administer warehouse operations from the time goods or materials enter a warehouse until they move out. Warehouses sit at the center of manufacturing and supply chain operations because they hold all the material used or produced in those processes, from raw materials to finished goods.

The purpose of a WMS is to help ensure that goods and materials move through warehouses in the most efficient, cost-effective way. A WMS handles many functions that enable these movements, including inventory tracking, picking, receiving and storage.

A WMS also provides visibility into an organization's inventory levels, aids in forecasting, facilitates inventory control, and advances material handling metrics at any time and location, whether in a facility or in transit.

Warehouse managers are the primary users of a WMS, but it can be integrated with enterprise resource planning (ERP), customer relationship management (CRM), transportation management systems (TMS) and inventory management. Someone in sales and marketing can research the WMS and obtain current statistics on how quickly sold items are located, collected and packed, then look at a TMS to find out how and when the product was shipped, and the estimated delivery date. All this data can be turned into performance reports.

This article is part of

Guide to supply chain management

Where WMS fits in the supply chain

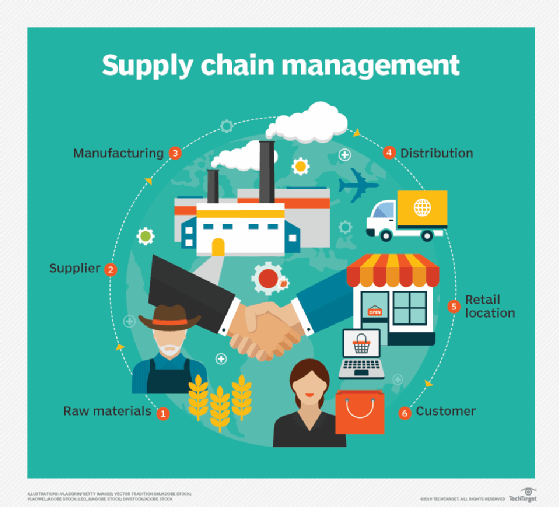

The supply chain, Figure 1, can operate only as quickly, accurately and efficiently as warehouse processes permit. A WMS plays a vital role in the optimization of supply chain management (SCM) by managing order fulfillment processes, from receiving raw materials to shipping finished goods.

If raw materials are not received properly or parts are misplaced, the supply chain might be slowed or disrupted. WMSes are critical in ensuring these processes work smoothly by tracking inventory and making sure goods are stored and sorted properly, and shipped and tracked accurately.

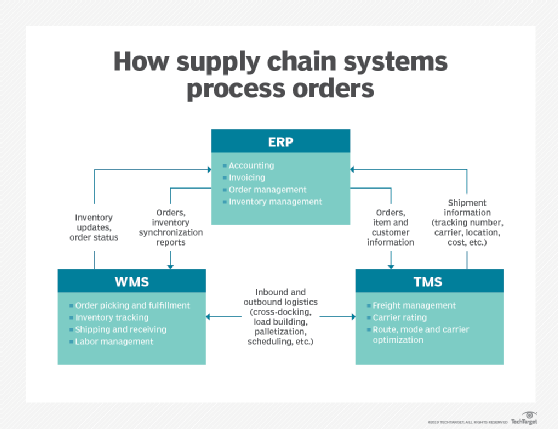

As Figure 2 shows, each of the three main SCM systems has a particular role in managing orders and sharing data with the other two.

The role of the WMS is to streamline warehouse automation by helping users manage the fulfillment, shipping and receiving tasks in the warehouse or distribution center, such as picking goods from shelves for shipment or putting received goods away. Its role in inventory is to track the inventory data that comes in from barcode readers and radio frequency identification (RFID) tags and update the inventory management module in the ERP system to ensure it has the latest information. An integration link synchronizes the inventory data stored in the ERP system and the WMS.

The ERP system handles the accounting and most of the invoicing, order management and inventory management.

The WMS is where shipping and receiving processes are managed. It is essentially a repository of detailed information about shipping carriers but is also a transaction-based communication system for planning, executing and tracking the shipments.

Sometimes, a TMS is integrated with a WMS to better coordinate inbound and outbound logistics tasks that occur at the interface of warehouses and freight shippers. Such tasks include palletization of goods, labor scheduling, yard management, load building and cross-docking.

Usually, orders come in automatically from ERP or order management systems integrated with the TMS. The ERP system also outputs the order information the TMS needs to prepare and execute shipments. Besides basics like customer name and address, data from the ERP system also includes detailed information on items to ensure the right products are shipped. The TMS returns the shipment details the ERP system needs for its accounting and order management functions, such as the tracking number, carrier name and costs. The shipment information might also go to a module to help update customers about order status.

Types of warehouse management systems

WMSes come in a variety of types and implementation methods. The type typically depends on the size and nature of the organization. Four types of WMSes are listed below:

- Standalone systems.

- WMS modules in SCM systems.

- WMS modules in ERP systems.

- Cloud-based WMS.

WMSes can also vary widely in complexity. Some small organizations might rely on simple hard-copy documents or spreadsheet files, but most larger organizations use complex WMS software.

Who uses warehouse management system technology?

Some WMS setups are designed specifically for the size of the organization and many vendors have versions of WMS products that can scale to different organizational sizes. Some organizations build their own WMS from scratch, but it is increasingly common to implement a WMS from an established vendor, especially cloud vendors.

A WMS can also be designed or configured for the organization's specific requirements. For example, an e-commerce vendor might use a WMS that has different functions than a brick-and-mortar retailer. A WMS might also be designed or configured specifically for the types of goods the organization sells. A sporting goods retailer, for example, would have different requirements than a grocery chain.

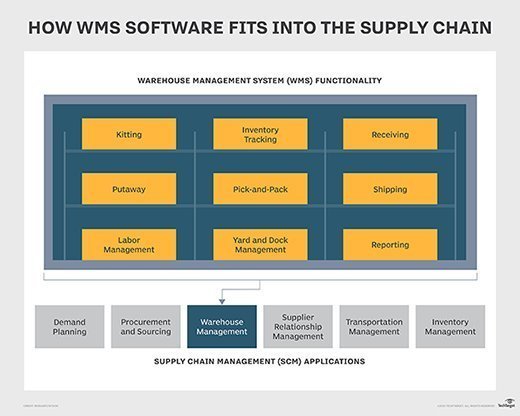

As depicted in Figure 3, WMSes play a vital role in SCM by ensuring efficient and cost-effective movement of goods and materials through warehouses. A WMS handles the functions that enable these movements, including inventory tracking, picking, receiving and storage.

Features of warehouse management systems

Many features shown in Figure 2 are common to WMS software products. They address the following:

- Warehouse design. This enables organizations to customize workflow and pick logic to ensure the warehouse is designed for optimized inventory allocation and movement. The WMS establishes bin slotting that maximizes storage space and accounts for variances in seasonal inventory.

- Inventory tracking. This accommodates advanced tracking and automatic identification and data capture (AIDC) systems, including RFID and barcode scanners to ensure goods can be found easily when they need to move.

- Receiving and storage. This facilitates inventory storage and retrieval, often with pick-to-light or pick-to-voice technology to help warehouse workers locate goods.

- Picking and packing goods. This includes zone picking, wave picking and batch picking. Warehouse workers can also use lot zoning and task interleaving functions to guide the pick-and-pack tasks most efficiently.

- Shipping. This lets the WMS send bills of lading ahead of the shipment, generate packing lists and invoices for the shipment, and send advance shipment notifications to recipients.

- Labor management. This helps warehouse managers monitor workers' performance by using key performance indicators (KPIs) that indicate when workers perform above or below standards.

- Yard and dock management. This assists truck drivers coming into a warehouse to find the right loading docks. A more complex use of yard and dock management enables cross-docking and other functions of inbound and outbound logistics.

- Reporting. This helps managers analyze the performance of warehouse operations and find areas to improve.

Cloud-based warehouse management system

WMSes, along with other enterprise systems such as ERPs, began as systems that were run on an organization's on-premises servers. This model has been transitioning to cloud-based WMSes, which are flourishing as organizations realize the benefits of running systems in the cloud.

With a cloud-based WMS, the WMS vendor or a cloud service provider hosts and manages the software. Non-cloud managed service providers (MSPs) might also support WMSes. This takes the burden of installing, managing and upgrading the system off the organization's IT department.

Small or medium-sized businesses (SMBs) like the ease of installation and lower costs that cloud-based WMSs provide. Larger enterprises often deploy on-premises WMS because they need highly customized systems that meet the requirements of their specific industry and they have the resources to manage the IT requirements. These systems might support specialized requirements, e.g., a short-term unique application, such as housing hazardous chemicals, which a cloud-based provider can implement quickly if needed.

Pros of cloud-based warehouse management systems

Benefits of a cloud-based WMS include the following:

- Faster implementation. Traditional on-premises WMSes can typically take months to implement, while cloud-based WMS deployments can be completed in weeks, depending on the complexity. This means that organizations have a faster path to a positive ROI and can take advantage of the cloud WMS capabilities sooner, which is a huge benefit in today's fast-paced economy.

- Fewer upgrade hassles. In the software-as-a-service (SaaS) deployment model for cloud-based WMS, vendors handle updates and configuration changes with regularly scheduled upgrades and patches. Being on the latest version of the software and associated patches means organizations spend minimal time and resources managing upgrades.

- Lower costs. Cloud-based WMSes cost less because they do not require hardware, software installation and IT administrators to manage them. Customizations or modifications, which can be costly for on-premises systems, are vendor-managed with client approval. Upgrades to on-premises systems can also be expensive, if they involve reinstalling and reconfiguring the software and upgrading the hardware.

- Scalability. Cloud-based WMSes can be scaled quickly as organizations grow and supply chains become more complex. They are more flexible and can be reconfigured as business requirements or market conditions change.

Cons of cloud-based warehouse management system

Drawbacks of a cloud-based WMS include:

- Long-term costs. While cloud-based WMSes often have lower upfront costs than on-premises systems, paying for licenses on a monthly or annual basis might be more expensive in the long run. Organizations might also incur additional costs for implementing new modules or premium support packages.

- Customization. Costs for customizing SaaS WMS software might be prohibitive, making it less suitable for organizations that need to modify the software to meet their specific processes or industry requirements.

- Updates and patching. Cloud-based WMSes are usually updated and patched on a regular basis. While this ensures that systems are always up to date, it might require that customers change processes periodically to keep up with the new software, and users might need retraining if the changes are significant.

All of the major WMS vendors (IBM, Microsoft, Oracle and SAP) offer a variety of deployment options, including cloud-based systems. WMS vendors that are primarily cloud-based or cloud-only include Fishbowl, HighJump and SnapFulfil.

Warehouse management system benefits

Although a WMS is complex and expensive to implement and run, organizations gain numerous benefits that can justify the complexity and costs.

Implementing a WMS can help an organization reduce labor costs, improve inventory accuracy, improve flexibility and responsiveness, decrease errors in picking and shipping goods, and improve customer service. Modern WMSs operate with real-time data, allowing the organization to manage the most current information on activities like orders, shipments, receipts and any movement of goods.

WMS and IoT

Connected devices and wirelessly connected products and materials help organizations ensure they can produce and ship the right quantity of goods, at the right price, to the right place, at the right time. The internet of things (IoT) has made all these capabilities cheaper and more pervasive.

IoT data can integrate into a WMS to help manage routing of products from the pickup point to the end point. The integration helps organizations develop pull-based, rather than push-based, supply chains. Customer demand drives pull-based supply chains, which can help the organization be more flexible and responsive. Long-term demand projections drive push-based systems.

WMS and artificial intelligence

A review of today's WMS (and ERP and TMS) offerings shows an increase in artificial intelligence (AI) functionality. This specialized technology can greatly enhance the performance of features described in the previous sections. AI can benefit warehouse managers by gathering data from other systems, such as a CRM or order processing system, finding where the required products are located, providing location details for parts pickers, tracking the packing process, and linking with a TMS to identify appropriate shipping arrangements.

Besides supporting warehouse functions, AI can also prepare reports analyzing how the warehouse is configured, recommend new locations for frequently selected products, examine how long products are stored before shipping, and even provide performance and efficiency reports on warehouse personnel.

In evaluating WMSes with AI elements, find out what AI functions are available, what they can do, and how much they must "learn" specific user requirements before being deployed. Generative AI features such as ChatGPT-like functions are being added to WMS products for report writing and other content activities.

Users must regularly review their requirements to identify opportunities where AI can provide added value.

Top warehouse management system vendors

Several large enterprise software vendors sell WMSes as standalone products or as modules in comprehensive ERP suites. These include the following:

- IBM.

- Microsoft.

- Oracle.

- SAP.

There are a variety of other prominent WMS vendors who focus on specific industries or company sizes such as SMBs, including the following:

- Aptean.

- ASCTrac.

- Blue Yonder.

- Click Reply.

- Epicor.

- Fishbowl.

- HighJump.

- Infor.

- Manhattan Associates.

- Sage.

- SnapFulfil.

- Softeon.

- Tecsys.

Understanding the different types of warehouse systems is key to creating efficient warehouses. Also, learn the differences between warehouse management systems vs. warehouse control systems vs. warehouse execution systems.