What is supply chain sustainability (SCS)?

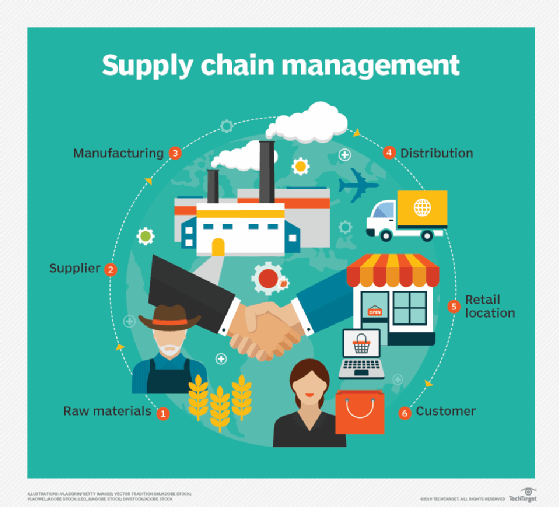

Supply chain sustainability (SCS) is a holistic view of supply chain processes, logistics and technologies that affect the environmental, social, economic and legal aspects of a supply chain's components. Typically, sustainability initiatives include identifying the source of raw materials, ensuring good conditions for workers and reducing the carbon footprint.

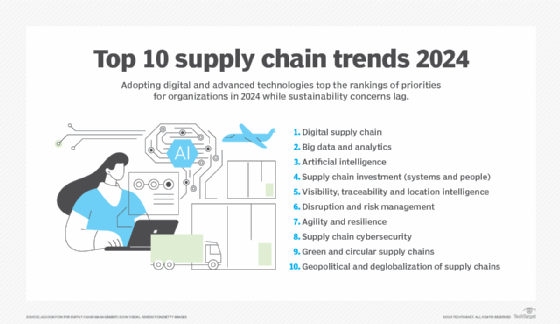

Historically, a supply chain was simply about logistics and knowing when and where goods were moving. The rise of the digital supply chain and the accompanying visibility, analytics and artificial intelligence tools has changed that. It has provided companies with the ability to gather data about how well each component in the supply chain demonstrates corporate social responsibility.

This transparency has promoted the concept of responsible sourcing and encouraged supply chain partners to develop and share best practices for green operations and logistics. It has also enabled prospective partners to demonstrate compliance with industry best standards for worker safety, environmental responsibility and business ethics.

Factors that affect SCS include the amount of waste generated and the carbon footprint created. More specifically it involves emissions, air pollution, labor violations, deforestation, and the health and safety of workers. SCS is based on the principle that socially responsible products, product design and business practices in general are good for the planet and the people who live on it. They're also good for building positive brand awareness, minimizing environmental impact and improving long-term profitability.

In large companies, a supply chain analyst or sustainability officer is often hired to handle the task of demonstrating SCS. In addition to developing and implementing sustainability programs and processes, the job can also include qualifying new suppliers, ensuring delivery and quality performance targets are achieved and supporting supplier diversity policies.

The importance of sustainability in supply chains

Sustainable supply chains minimize waste, conserve natural resources and reduce environmental harm. Cost savings can result from specific sustainable practices, such as switching to reusable materials. In addition, a business that's mindful of SCS practices also improves its reputation among consumers, which can have positive financial implications.

Supply chain sustainability also encompasses adhering to socially acceptable labor practices and respecting human rights. Following SCS best practices helps companies avoid reputational harm that can result from providing poor working conditions and following other negative practices.

Customers who are environmentally savvy are more likely to buy from companies that offer supply chain transparency. A broader sustainability strategy will ensure public trust in the long run.

The 3 pillars of sustainable supply chains

Sustainable supply chains are based on environmental, social and economic attributes. These factors make up the three pillars of SCS:

- Environmentally sustainable. Businesses and other organizations can recycle product waste that would otherwise end up in landfills. They can conserve natural resources such as water and monitor energy use to reduce greenhouse gas emissions. However, it's also a collaborative effort in that the suppliers from which a business gets goods and services must also adhere to these practices.

- Socially sustainable. Businesses should treat workers with dignity, adhere to fair labor practices, and provide acceptable and safe working conditions. This pillar also involves supporting local community development. Being cognizant of the social impact of supply chain management makes a business a more appealing partner to customers and shareholders.

- Economically sustainable. This pillar is based on a combination of factors within a supply chain leading to long-term financial stability for a business. These factors might include switching to reusable materials to reduce product costs, improving working conditions to attract and retain employees, and having risk management policies in place.

Benefits of supply chain sustainability

When the three SCS pillars are considered of equal importance, a business likely benefits in various ways. These include an improved bottom line, more satisfied employees and a healthier environment both inside the workplace and in the community in general. Other benefits include the following:

- New partnerships. Businesses or suppliers that are transparent in proving sustainable supply chain management will draw interest from others who are adamant about these issues, thereby creating a supply chain of partners interested in sustainability.

- Risk mitigation strategies. In crafting policies centered around workers and the environment, a business is proactive in mitigating risks that could arise from poor working conditions and other issues.

- Stakeholder attraction. Businesses with sustainable supply chain operations attract new stakeholders, such as investors, who value sustainability, which bodes well for financial stability.

- Compliance. As new laws and regulations are created, businesses not only improve their supply chains, but also meet these new standards intended to protect workers and the environment.

Challenges of supply chain sustainability

Achieving sustainability in supply chains takes time and effort, and it isn't always a smooth process. Multiple challenges can create barriers, including the following:

- Lack of sustainable materials. A business might have limited options when it comes to the procurement of the materials or components needed to produce and package goods. Extra effort and expense might be required to source materials responsibly from the right suppliers.

- Short-term costs. Smaller businesses, in particular, with sustainability goals could have difficulty setting up the needed SCS infrastructure. For instance, inventory management software can be expensive for smaller businesses.

- Visibility challenges. Visibility into production and logistics operations is harder to achieve in large and global supply chains unless sophisticated management software is used to streamline this. Even then, tracking the disruptions and bottlenecks that are likely to occur with more parties involved in a supply chain is still challenging.

- Long-term planning. Setting long-term goals is just the first step in the planning process. However, long-term planning is becoming more difficult with the uncertainties related to political upheaval, climate change, pandemics and other global issues. Supply chains will need to be adjusted with sustainable sourcing and the right tools, such as traceability software, that can help a business achieve SCS goals.

How to improve supply chain sustainability

Companies should take the following steps to achieve a more sustainable supply chain:

- Identify critical issues and areas for continuous improvement within the entire supply chain. The environmental impact of a supply chain is a culmination of each step in the production and operation process. Therefore, companies must understand where the most emissions and risks are in order to support data-driven decision-making and make improvements.

- Use supply chain management and measurement tools to help track progress and find weaknesses. Organizations such as The Sustainability Consortium, World Wildlife Fund and the Sustainability Accounting Standards Board have created guidelines, benchmarks, metrics and key performance indicators that can help consumer businesses move toward their environmental goals.

- Set supply chain sustainability goals that reflect global sustainability development goals. Companies should model sustainability efforts around scientific recommendations and government regulations to contribute the greatest impact to the global sustainability agenda.

- Choose and collaborate with other sustainable suppliers. The practice of collaboration and combination of resources between manufacturers can help organizations reduce waste, costs and environmental risks. For example, sharing modes of delivery with other companies can reduce pollution by reducing the number of half-empty vehicles traveling the same route.

- Maintain accountability throughout the process. Processes should be implemented that ensure liability, such as routine audits, implementation of sustainability standards, software tools for tracking the effect of sustainability efforts, customer-facing goals and progress reports.

- Purchase carbon offsets. Organizations that have less control over supply chain or want to begin making an immediate impact can buy carbon offsets. These are credits that help negate an organization's carbon emissions by investing in eco-friendly initiatives.

Sustainable supply chains vs. other supply chains

Sustainable supply chains combine the strengths of green supply chains, as well as ethical and responsible supply chains. Green supply chains focus on reducing pollution and waste, among other natural resource concerns. Responsible and ethical supply chains focus on fair labor practices, good working conditions, fair compensation and other worker-related and broader social sustainability issues.

A sustainable supply chain will adhere to both socially and environmentally acceptable business practices. However, that doesn't mean a responsible or green supply chain can't improve and eventually become fully sustainable. For example, a green supply chain mainly concerned with environmental waste can become sustainable once the business expands its focus to worker and social issues.

Real-life examples of supply chain sustainability

Various industries use supply chain practices that are ethical, socially responsible and environmentally friendly. The following three case studies show how SCS is beneficial in real-world scenarios:

- E-commerce and retail. Sustainable e-commerce supply chains involve responsible extraction of raw materials, as well as waste reduction by recycling and reuse and managing carbon emissions. Additionally, using inventory management software means companies keep tabs on inventory levels to minimize waste.

- Healthcare. Suppliers in this industry who use sustainable packaging materials and offer transparency into how they source raw materials provide their healthcare customers SCS assurances. Hospitals and healthcare providers use inventory management systems to reduce waste.

- Food and beverage. Food supply chains can be optimized with sustainable agriculture practices -- such as conserving water resources -- and the use of recyclable packaging. Socially acceptable working conditions and fair labor practices for farmers and agricultural and food industry workers are also important elements.

Business leaders and corporate board members must be strategic and proactive about sustainability in their supply chains. Learn the necessary steps for sustainable supply chain practices.