logistics

What is logistics?

Logistics is the process of planning and executing the efficient transportation and storage of goods from the point of origin to the point of consumption. The goal of logistics is to meet customer requirements in a timely, cost-effective manner.

Originally, logistics played the vital role of orchestrating the movement of military personnel, equipment and goods. Today, the term logistics applies to any context that requires moving commercial goods within the supply chain.

Many companies provide logistics services to manufacturers, retailers and other industries with a large need to transport goods. Some of these logistics providers own the full range of infrastructure, from jet planes and trucks to warehouses and software, while others specialize in one or two parts. DHL, FedEx and UPS are well-known logistics providers.

Typically, large retailers and manufacturers own major parts of their logistics network. Most companies, however, outsource the function to third-party logistics (3PL) or fourth-party logistics (4PL) providers. A business might turn to a 3PL provider to manage specific aspects of logistics, such as warehousing, while retaining some oversight of these operations. Businesses outsource all aspects of logistics to 4PL providers, including oversight and management. Outsourcing an entire supply chain relieves customers of time-consuming and costly logistics processes.

This article is part of

Guide to supply chain management

What are the functions of logistics?

Transportation and warehousing are the two major functions of the logistics industry. Transportation management focuses on planning, optimizing and executing the use of vehicles to move goods between warehouses, retail locations and customers. The transportation is multimodal and can include ocean, air, rail and roads.

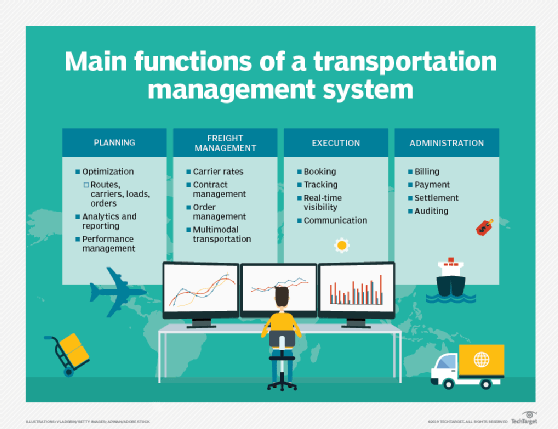

Not surprisingly, transportation management is a complex process that involves planning and optimizing routes and shipment loads, order management, freight auditing and payment. It can also extend to yard management, a process which oversees the movement of vehicles and fleet management through the yards outside manufacturing plants, warehouses and distribution centers. Carrier management is an important aspect since the price, availability and capacity of transportation carriers varies widely.

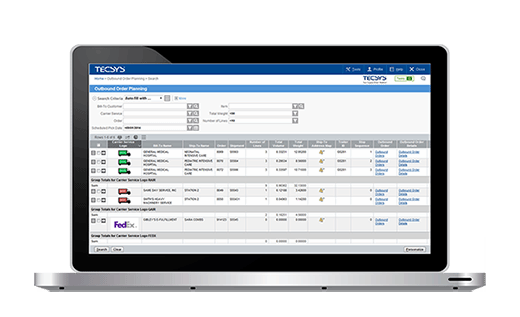

Logistics companies typically use transportation management system (TMS) software to help meet the demands of transport-related logistics. There are also niche applications, such as yard management systems and warehouse management systems (WMSes).

Warehousing, or warehouse management, includes functions such as inventory management and order fulfillment of customer demand. It also involves managing warehouse infrastructure and processes; for example, in a fulfillment center, orders for goods are received, processed and shipped to the customer. Most companies use WMS software to manage the flow and storage of goods and track inventory. Enterprise resource planning software vendors typically offer TMS and WMS modules, as well as specialized components for inventory control and other logistics functions.

Customs management, also known as global trade management, is often considered part of logistics. The paperwork to show compliance with government regulations usually is processed where goods cross national borders or enter shipping ports.

Why logistics is important

On-time delivery of intact packages has always been important throughout the supply chain process. However, it has become even more critical in recent years as omnichannel commerce has becomes more common, with its same-day home and retail delivery of customized products ordered from smartphones.

Suppliers, manufacturers, distributors and retailers have had to improve their logistics processes to meet the demand for faster, more convenient delivery of a large number and variety of goods. They also have had to better integrate their processes and systems, implementing ways to improve supply chain visibility.

Understanding logistics in business

The importance of logistics is particularly clear when examining the business supply chain. In business logistics, the individual processes involved in transporting and storing goods are managed holistically and viewed by management as one, unified system.

Some of the components that function as part of that unified system include the internal teams and third-party contractors that handle forecasting and planning, transportation, order processing, customer satisfaction and service, and warehousing. Manufacturing plants may handle certain processes themselves but then outsource other processes to outside entities.

A liquified natural gas terminal is an example of a business context where effective management of multiple logistic processes is critical. Various teams must handle the transportation, processing and storing of natural gas products. The many moving parts involved must be well managed or else the overall process will break down, a situation that could be dangerous given the volatile nature of natural gas.

Difference between logistics and supply chain management

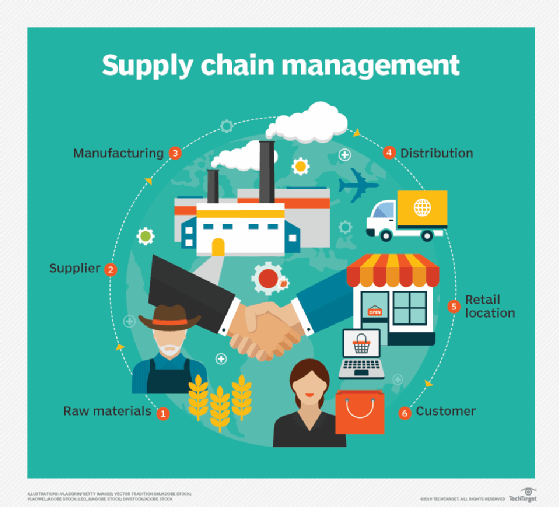

Logistics management is an important component of supply chain management (SCM), and the terms are sometimes used interchangeably.

Logistics management

Logistics management focuses on materials handling and managing the movement of finished products as efficiently as possible. Sometimes, the terms inbound logistics and outbound logistics are used to denote logistics for goods arriving at or leaving a facility, respectively.

Another important category of logistics management is reverse logistics. This is the process used to return a product to a distribution center for servicing, refurbishing, decommissioning and recycling. This is especially pertinent to e-commerce.

Supply chain management

SCM encompasses a much broader range of supply chain planning activities. These include demand planning, sales and operations planning, and supply chain execution, including strategic sourcing and transportation management.

Different types of logistics

There are several phases within a typical supply chain, from sourcing raw materials, to creating or manufacturing the products, to delivering them to end users or businesses. Each phase can use a different type of logistics. Inbound, outbound and reverse logistics are among these types, but there are others, such as the following:

- Procurement logistics. This encompasses finding and contacting the needed suppliers for raw materials and anything else needed to begin the production phase. It's important to choose the correct amount of materials and have them delivered in a timely manner.

- Production or manufacturing logistics. Multiple processes are encompassed here. These include the creation, in-house transport and storage of a new product, as well as any efforts to optimize these processes and reduce the time and cost required to meet a consumer's product order.

- Distribution logistics. The timely delivery of a product to a consumer can take place either directly, where a manufacturer is tasked with delivery to end users, or indirectly, where a retailer or wholesaler is tasked with selling and delivering to end users. Distribution logistics is also focused on optimization of packaging and shipping methods.

- Disposal logistics. This type of logistics spans the entirety of the supply chain because every phase is prone to waste. It's similar to reverse logistics, yet different in that it encompasses disposal processes as well. Residual materials can be recycled or recovered to maximize efficiency; any material deemed unusable can be disposed of.

The future of logistics

Artificial intelligence (AI) and automation will play important roles in how logistics operates in the future. Transportation in particular and the logistics functions related to it will rely on AI systems to automate repetitive tasks so logistics experts can focus on more important or innovative work. Some logistics providers are already using AI to track packages and predict transport-related problems in the supply chain. Additionally, other technologies like radio frequency identification systems are used to track the whereabouts and conditions of goods in real time and provide automatic updates.

Meanwhile, driverless vehicle technology, such as driverless forklifts, delivery trucks and drones, is likely to become commonplace in warehouses and warehouse yards, as well as on highways. Challenges remain, but business will want the efficiency they provide as they use data to identify the most optimal routes to shorten delivery times.

Industry 4.0, the cyber and digital transformation of manufacturing, includes logistics 4.0 as one of its subfields, in which emerging technologies are coming together to modernize logistics. These include big data, AI analytics and IoT.

Learn more about the role of logistics in supply chain management in our comprehensive guide.