What is demand planning and why is it important?

Demand planning is the process of forecasting the demand for a product or service so it can be produced and delivered more efficiently and to the satisfaction of customers. Demand planning is considered an essential step in supply chain planning.

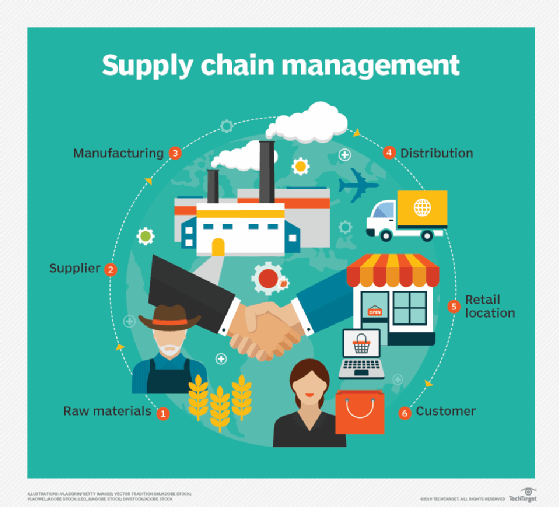

Supply chain execution and supply chain planning are the two major components of supply chain management. The planning side of SCM typically starts with demand planning, which involves creating a demand plan based on a statistical forecast that considers factors that can influence demand -- such as inventory and marketing -- and specifies where to distribute products to meet the anticipated demand. The demand plan feeds into the next steps in the supply chain planning process: material requirements planning (MRP) and production planning. Once the product is manufactured, it enters the execution stages of SCM, including warehouse and transportation management.

Sales managers, marketers and manufacturing, finance and production managers are typical members of a demand planning team. Some companies have dedicated staff with titles such as demand planner and demand planning analyst. The demand planner usually leads the team.

How does demand planning work?

Demand planning works by forecasting customer demand and aligning it with supply chain management processes to ensure the right products are available at the right time.

This article is part of

Guide to supply chain management

The demand planning process starts by analyzing historical data, market conditions and variability to create an accurate forecast of future demand. This information can help companies anticipate inventory needs and manage new products and product lines, in turn improving profitability and customer satisfaction.

Demand planning often uses tools such as regression analysis and automated systems to refine forecasts and adapt strategies to handle potential disruptions. This can also help organizations reduce unnecessary costs and adapt to evolving trends and market conditions.

Importance of demand planning

Keeping up with product demand is critical, as failing to do so can result in lost revenue for the product or, even worse, lost customers. One of the main goals of demand planning is to have just the right amount of inventory to meet customer demand without incurring shortages or wasting money on making and storing surplus inventory.

Demand planning can also help minimize the bullwhip effect, a phenomenon in which small fluctuations in retail demand amplify demand from earlier actors in the supply chain, such as suppliers and manufacturers. More accurate demand forecasts and better communication among supply chain participants can help to minimize the bullwhip effect.

Elements of demand planning

Demand planning is a complex process that typically includes the following elements:

- Data collection from internal and external sources on the factors known to predict or influence demand.

- Statistical analysis of sales, inventory and other data.

- Data modeling to predict future demand.

- Collaboration with suppliers, manufacturers, salespeople and other stakeholders to gather information on events that could affect demand, such as promotions and production delays.

The above processes lead to the creation of the following:

- Demand forecast. A prediction of demand based on the data model and analysis, followed by a demand plan.

- Demand plan. An outline of the amount, type and location of inventory needed to satisfy the forecasted demand.

Beyond these basic functions, some demand planning strategies incorporate the following processes, at least in part:

- Product lifecycle management. PLM analyzes factors that contribute to the demand for different products.

- Replenishment planning. This process ensures that inventory is in the right locations and in quantities to meet the demand.

Key steps in demand planning

Demand planning starts with preparing a statistical forecast of how much inventory is needed. To do this, a planning team is usually assembled from the sales and marketing departments and from operational departments, including finance, production and procurement. There might be a dedicated demand planning analyst who provides expertise in data management and statistics, as well as someone who can act as a liaison to the IT organization to address technical aspects of the software, such as forecasting algorithms, data reporting and integration.

The team starts by reviewing the available information, such as the sales forecast, historical sales data, market research and surveys. Often, this involves collecting point-of-sale (POS) terminal data and analyzing it with the analytics tools in demand planning software, which might be a standalone system or part of an SCM or enterprise resource planning software suite. Some companies store POS data along with other demand signals, such as retail and wholesale inventory levels and data from loyalty programs, in a type of data warehouse called a demand signal repository.

Inventory data can help put sales data in proper perspective by, for example, identifying sales lost due to inventory stockouts, which point to a higher demand than indicated by sales alone. Using analytics to find such relationships between sales and inventory can ultimately improve forecast accuracy.

The demand planning team then agrees on a forecasting model it believes will be the most effective at predicting demand. The team can add new data as it comes in, such as actual sales of a product or competing products, and revise the model and resulting forecasts if necessary.

Demand planning is often conducted in the early stages of sales and operations planning (S&OP), a process for aligning supply with demand by coordinating sales planning and forecasting with production planning in a unified approach.

Product lifecycle management influences demand planning by serving as a source of detailed product information. Conversely, demand planning plays a role in PLM. For example, companies can use demand planning to predict the demand for a proposed product by comparing it to similar products and seeing how certain features might affect demand.

Demand planning best practices

There are several important best practices to employ with demand planning, including the following:

- Use data concerning past demand patterns to make more accurate forecasts.

- Implement automation to reduce human error, a top security issue, and speed up demand planning processes and decision-making.

- Incorporate seasonality and market conditions in forecasts to anticipate demand spikes or slow periods.

- Prioritize customer satisfaction by aligning inventory with customer needs, avoiding overstock and stockouts.

- Monitor key metrics, such as inventory turnover, forecast accuracy and stock keeping unit (SKU) performance.

- Use optimization techniques to adjust product portfolio and product lines based on demand.

- Plan for disruptions by building flexible processes that can respond to unexpected changes in demand.

- Align with the supply chain management process to ensure coordinated supply and demand activities.

Demand planning vs. demand forecasting

Demand planning has much in common with demand forecasting, though most experts consider demand planning to go beyond statistical forecasting to include planning the scope of the inventory.

Both terms are sometimes used as synonyms for demand management, but they are usually regarded as distinct components of it. Demand management also includes demand shaping, the process of trying to affect demand through price changes, product substitution, promotions and other methods.

Making matters more complicated, it could be argued that demand planning is a bit of a misnomer, as most of the critical planning occurs in later processes, such as S&OP, MRP and production planning.

Future of demand planning

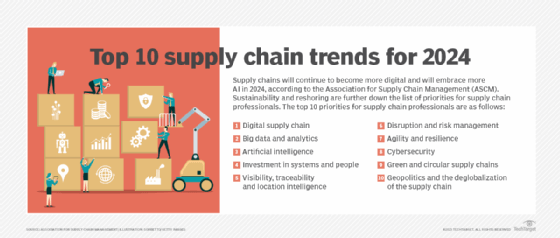

The increasing availability of more real-time data -- some of it transmitted by internet of things sensors -- and of advanced analytics employing machine learning and other artificial intelligence techniques are helping to improve forecast accuracy. Meanwhile, cloud-based collaboration tools and mobile devices are enhancing the ability of demand planners to share information and react more quickly to changes in supply and demand.

More broadly, digital transformation -- the drive toward more fully digitized business processes -- is gradually connecting more supply chain participants, from the consumer to the manufacturer to the raw materials supplier, and providing finer-tuned control over the movement of goods. These broader trends lend new support to a longstanding effort to build what some vendors and industry analysts call the demand-driven supply chain, in which supply is more responsive to actual consumer demand and not primarily the product of an educated guess.

Digital demand management is one of these trends, making use of advanced digital tools and technologies to manage demand forecasting, inventory optimization and supply chain coordination. By integrating machine learning and artificial intelligence, digital demand management can analyze large amounts of historical data to provide accurate forecasts, even for highly variable product portfolios and SKUs. This digital approach automates much of the demand planning process, making it faster, more accurate and less prone to error and supply chain disruptions.

Demand planning is an integral part of supply chain management. Learn about the top supply chain management career paths.