What is Open Platform Communications (OPC)?

Open Platform Communications (OPC) is an interoperability standard for secure data exchange in industrial automation and other areas. It is designed to be platform-independent so devices from different vendors can exchange information. The original standard was limited to Microsoft technologies, so its application was restricted to Windows systems, but the standard is now more platform-independent, scalable and extensible.

The OPC standard has come to play a vital role in Industry 4.0, a movement toward smart manufacturing that embraces digital transformation and cutting-edge technologies, including artificial intelligence (AI) and industrial internet of things (IIoT).

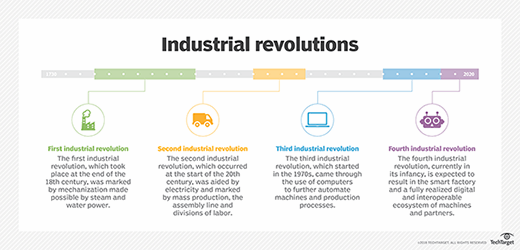

Industry 4.0 represents the fourth industrial revolution, which emphasizes communication and interoperability.

The OPC standard enables systems to communicate more efficiently and effectively, making it possible to collect and analyze information from every part of the manufacturing process. This helps to break down data silos, improve efficiency and responsiveness, and facilitate better business decisions.

History of Open Platform Communications

In 1995, four industrial automation vendors launched a task force to standardize the data-access protocols across their devices. At the time, those devices predominantly ran Microsoft operating systems. The task force devised a plan to abstract the communication protocols used in programmable logical controllers (PLCs), which are small, special-purpose computers widely deployed in industrial environments to control manufacturing systems and processes.

The initial specification abstracted the protocols into a standardized interface that converts read/write requests between human-machine interface (HMI) and supervisory control and data acquisition (SCADA) systems. An HMI is a user interface that enables operators to interact with machines and systems via a PLC, and SCADA is a popular computer architecture commonly used for industrial process control. The OPC interface converts device-specific requests into generic OPC requests and converts generic OPC requests into device-specific requests.

In 1996, the task force released version 1.0 of the OPC standard, later dubbed OPC Classic. Not long after, other hardware and software vendors adopted the new standard. This led to the formation of the OPC Foundation in 1996 to formalize compliance, certification, interoperability and validation procedures. The foundation continues to create and maintain the OPC specification and ensure compliance through certification testing.

OPC Classic specifications

The first version of the OPC standard was based on the Distributed Component Object Model (DCOM), a Microsoft technology for exchanging data between software components across a network. As the name suggests, DCOM is a subset of the Component Object Model (COM), an object-oriented approach to creating binary software components.

Originally, the OPC acronym stood for OLE for Process Control because the Object Linking and Embedding (OLE) technology played such a key role in Windows environments and subsequently the OPC standard. OLE is a Microsoft COM desktop technology for embedding and linking documents and other software objects.

The OPC Foundation divides OPC Classic into three specifications:

- OPC Data Access (OPC DA). First released in 1996, the specification defines the OPC client-server architecture for exchanging data. It details how software can read and write data, and the data types and structures available.

- OPC Alarms and Events (OPC AE). First released in 1999, the specification describes the ways OPC server software can monitor systems and send alarms to client software.

- OPC Historical Data Access (OPC HDA). First released in 2001, the specification defines the queries and analytics that can be applied to the historical time-stamped data collected from devices.

In 1998, the OPC Foundation began to convert the original OPC DA specification to web services. Then, in 2006, the foundation released the OPC Unified Architecture (OPC UA) specification, the next generation of the OPC standard.

OPC Unified Architecture specifications

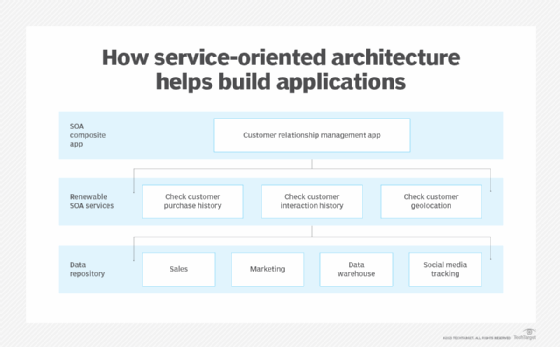

In 2006, the OPC Foundation released version 1.0 of OPC UA. The new standard was developed in part because Microsoft was moving away from DCOM toward a service-oriented architecture (SOA). SOA is a software design approach that incorporates reusable services capable of communicating across different platforms and languages.

At the time, many industries had already incorporated SOA into their manufacturing processes. Vendors also wanted to expand their OPC software to non-Windows platforms, including embedded devices. The OPC UA standard sought to accommodate these trends, while still providing backward compatibility with OPC Classic.

OPC UA offers an extensible SOA framework designed to support a wide range of platforms, from embedded microcontrollers to cloud infrastructure. It goes beyond OPC Classic by adding several important capabilities:

- Platform independence across hardware architectures and operating systems.

- Complete mapping between the OPC Classic specifications and the new OPC UA.

- Greater security through encryption, authentication and auditing.

- An extensible, multi-layered architecture that supports the addition of new features while maintaining backward compatibility with existing products.

- An information modeling framework that enables developers to model and extend complex multi-level data structures.

The OPC UA standard, now at version 1.05, is composed of 24 core parts, which were published individually between 2021 and 2023. The OPC Foundation also provides downloadable COM proxy wrappers for integrating OPC UA and OPC Classic products.

As of mid-2024, the OPC Foundation claimed over 920 member companies and thousands of OPC-compliant products. Members include leaders in the software, hardware, industrial automation, machine-to-machine (M2M), smart energy, and discrete- and process-manufacturing sectors. Among the most well-known companies are Honeywell, IBM, Microsoft, Rockwell, SAP and Siemens.

Learn about potential IIoT use cases, as well as more of its advantages and challenges and explore how to overcome common IIoT adoption issues. Also, read about factors to consider when securing industrial IoT networks.