Photo-K - Fotolia

What are the advantages of cycle counting?

If you're looking for that holy grail of 98% inventory accuracy, cycle counting can help. Here's how to move away from taking only periodic inventory counts.

An inventory record accuracy validation and improvement technique that is vastly superior to periodic physical inventory counting, cycle counting is a continuing process in which a selected sample of items is counted each day (or week). With cycle counting, important items are counted more frequently than less important items. The key to cycle counting is in setting up the "cycles."

In virtually every case, companies find that 20% of the items in stock account for 80% of the total dollar value that flows through the warehouse. The next 30% of items make up only 15% of the money flow, while the remaining half of the items account for only 5%. Applying this "80-20 rule," also called Pareto Analysis, leads to the conclusion that the top 20% of the items should get the most attention, receive the closest management and should be counted more often.

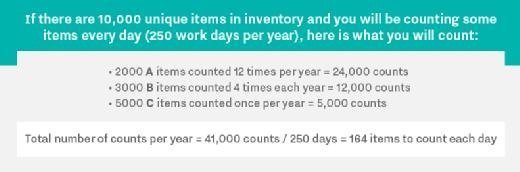

Setting up a cycle counting program involves dividing the items into groups: Group A for the top 20%; group B for the next 30%; with the remainder going into group C. Let's say, for example, that you want to count the A items monthly, the B items quarterly and the C items once per year. The image below shows what that would look like.

Your ERP or inventory system should be able to assign the items to the groups and produce count lists in such a way that each day's list will contain the right number of A, B and C items to cycle through in the expected frequency. It will go through the entire list of A items in about 21 days (one month of work days, or about 95 A items each day), about 48 B items each day and about 20 C items.

Cycle counting becomes a routine daily or weekly activity that provides a real opportunity to find the source of errors (only a few weeks and few transactions to review to find the source of the error) and improve procedures to prevent reoccurrence. Companies not using cycle counting typically maintain inventory accuracy levels in the 40% range (of 100 items counted, only 40 or 50 are correct). A well-executed cycle counting program can raise that accuracy level into the 90s in a relatively short time and help maintain at least a 98% accuracy level over the long term.