The ultimate guide to ERP

ERP is the nervous system of modern businesses. Learn how it works, understand its risks and benefits, and get tips on deployment in this wide-ranging guide.

It is hard to imagine modern business without ERP. From its roots more than 50 years ago in the first financial and production planning tools used by manufacturers, ERP has grown to become a mainstay in all but the smallest businesses.

ERP, or enterprise resource planning, is networked software that handles the transactions and record-keeping of the essential functions of any business, such as sales, purchasing, accounting and human resources. Installing an ERP system is one of the boldest steps an organization can take to computerize its business activities because it replaces most separate applications and manual processes in one fell swoop.

Read on to learn the basics of ERP and the steps to deploy it, and click on the links for more detail and in-depth analysis.

What does an ERP system do?

ERP software consists of connected but distinct components, or modules, each of which enables workers to carry out the functions of a particular business process or department, such as sales, customer relationship management (CRM), inventory management and finance.

ERP differs in essential ways from other types of business software -- say, basic accounting, scheduling or task management -- that is used by one person or a small group and has no direct connection to other software.

An important differentiating feature of ERP is the integration between modules that enables the modules and users to interact. For example, a sales order created in the CRM module will be shared with the production module so workers in the manufacturing department will have the information about what product to make. When the product is shipped, data in the inventory management module changes, and when the customer pays, the accounting module records the revenue.

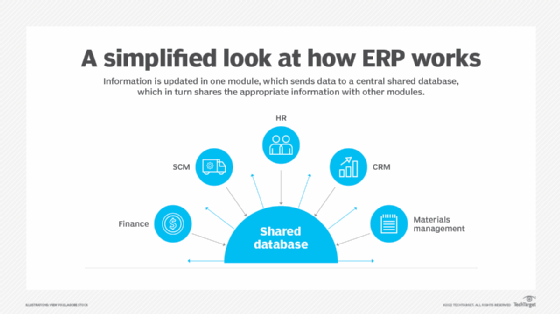

Another distinguishing feature of ERP software is the central database in which the modules record transactions and other information, access that data and share it (see Figure 1). Having this "single source of truth" -- that's an IT industry buzz phrase -- saves users from having to enter information more than once. It also improves data accuracy and facilitates reporting and collaboration.

ERP also usually maintains a consistent look and feel across modules, unlike a collection of separate software applications from different vendors. This consistency, at least in theory, makes it easy for workers to learn the system and move around the modules. In reality, many people find ERP software difficult to use -- especially if it is a decade or two old and hasn't been updated with graphical user interfaces (GUIs) and other usability improvements.

What are the advantages and disadvantages of ERP?

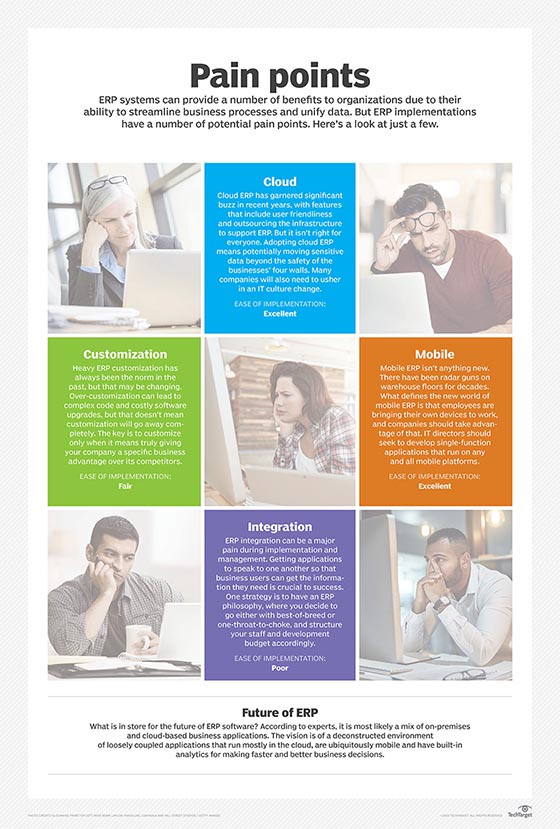

The sheer size, interconnectedness and complexity of ERP is both a blessing and a curse (see Figure 2).

When ERP software is running well and closely aligned with an organization's ways of doing business, it makes important business processes function more smoothly and opens up new possibilities, such as redeploying workers or implementing an omnichannel e-commerce strategy. But when deployment is delayed or the system goes down unexpectedly, ERP can bring business to a standstill and force users to scramble, looking for manual alternatives. And an older ERP system with unintuitive screens and poorly designed workflows can put a drag on a business that threatens its very existence. That's why it's important to have a formal ERP maintenance plan and perform periodic checkups of important variables that affect reliability, such as disk capacity and software updates.

But the biggest disadvantage of ERP -- one that has led to lawsuits -- is the significant risk and cost of a failed or severely delayed implementation. ERP implementation failures often make headlines; at least two such failures involved projects that topped $1 billion. One high-profile case was the 2018 suit that investors of cosmetics maker Revlon filed when problems implementing SAP ERP allegedly disrupted manufacturing operations and delayed shipments.

Nevertheless, the advantages of ERP usually outweigh the disadvantages. Among the highlights are the following:

Advantages

- ERP can save money over the long run by streamlining processes.

- It provides a unified system that can lower IT, labor and training costs.

- ERP enables a clearer view into critical parts of the business, such as sales, working capital and inventory.

- It facilitates reporting and planning through improved data and analytics.

- It offers better compliance and security through standardized workflows and fine-grained control of user rights.

Disadvantages

- ERP software can be expensive to buy, deploy and maintain.

- It is often difficult to implement.

- It requires significant training and change management.

- It can be complex, especially when it's heavily customized

- ERP modules are often less sophisticated than specialized software and go unused or must be replaced.

Key features of ERP systems

Most ERP systems handle the core business processes -- either in dedicated modules or in subfunctions of other modules -- that are common to all kinds of enterprises. However, the ERP finance module is the only one in every ERP product, since every company needs the ability to process financial transactions and account for them. It automates basic accounting, invoicing, financial analytics, forecasting and reporting.

The ERP HR module is usually second in importance because any company complex enough to need ERP probably also needs tools for managing payroll, benefits and employee records.

Other commonly used core ERP modules include order management, sales management or CRM, and purchasing or procurement.

Companies that make or distribute products need additional modules with specialized capabilities. The most common ones include the following:

- Material requirements planning (MRP).

- Inventory management.

- Manufacturing management (production management).

- Supply chain management (SCM): complex processes for demand planning and logistics, including transportation management systems and warehouse management systems.

Some organizations add still another layer of modules that are even more specialized or provide advanced capabilities. For example, a company might augment the basic HR functions that came with the ERP system -- such as payroll, benefits and employee records -- with talent management software that includes modules dedicated to recruiting, training, evaluating and compensating employees. A consultancy, construction firm or other business whose work is typically organized into projects might add a project management module. A manufacturer with its own distribution centers might buy an SCM suite from another vendor that has sophisticated transportation and warehouse management software that comes with prepackaged integration to the ERP.

On-premises ERP vs. cloud ERP vs. hybrid ERP

ERP systems are designed to run either on premises in the owner's data center, or in the cloud on computers maintained by the vendor or a partner and delivered to users over the internet.

Choosing a deployment option is one of the biggest decisions an ERP buyer has to make because it affects almost every aspect of an ERP system, including the types of features that are available, implementation time, user-friendliness and cost.

Early cloud versions of ERP had fewer modules and capabilities than on-premises versions. Today, the two systems have neared parity, with cloud deployments offering some important advantages.

In most cases, cloud ERP doesn't require the computing infrastructure of on-premises ERP. Instead, the software vendor or cloud service provider manages it. A cloud ERP implementation can therefore be far cheaper in terms of purchase, deployment and maintenance costs.

Thanks to the flexibility of cloud computing resources, cloud ERP can be easier to scale up and down as needs fluctuate. Automatic upgrades, which are also managed by the vendor, can deliver new technologies faster and with less hassle than is possible with on-premises ERP.

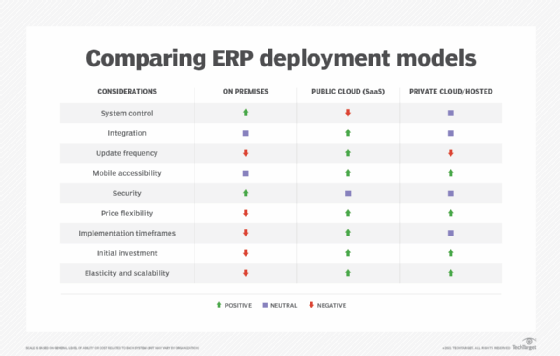

However, not all cloud ERP deployment options are alike, and ERP vendors often fudge the terminology (see Figure 3). Options include the following:

- Multi-tenant. The purest type of cloud ERP, multi-tenant SaaS ERP, is usually streamlined with fewer modules and features than on-premises ERP. Multiple users share the same copy of the software, which makes it cheaper, simpler and more standardized than most on-premises ERP.

- Single tenant. Another type of SaaS, called single tenant, cordons off the software to give the buyer more control over the ERP, including some ability to customize it, which is usually not possible with multi-tenant SaaS.

- Private cloud and hosted ERP. Two other varieties of cloud ERP, private cloud and hosted ERP, typically just involve running the same on-premises software on an outside provider's data centers, though they may have some characteristics of cloud computing such as economies of scale from shared infrastructure as well as on-demand use and pricing. Some companies maintain their own private cloud infrastructure -- a good example of how much the lines between on-premises and cloud ERP have blurred.

- Hybrid ERP. The fact that SaaS ERP, particularly multi-tenant, usually can't be customized is a major drawback for companies that need the custom features and integrations of an on-premises ERP system into which they have usually sunk significant time and money. As a result, hybrid ERP, which combines on-premises and cloud ERP modules and related applications, is an increasingly popular way to gain some of the technological benefits of SaaS without losing the security of an older, familiar system. Often, it's used to extend an on-premises system with SaaS ERP systems -- sometimes from different vendors -- for new remote offices or divisions, an approach sometimes referred to as two-tier ERP. Regardless of the purpose, hybrid ERP raises daunting integration challenges.

Payment terms also vary for the different types of ERP deployments. Unlike on-premises ERP, which usually requires an expensive long-term license paid upfront, SaaS is generally sold as monthly per-user subscriptions. However, the differences between cloud ERP and on-premises ERP pricing aren't always so clear-cut because many vendors combine features of the two.

How to choose an ERP system

Finding an ERP product that will fit the organization's needs requires following a methodical process that typically includes these major steps:

- Assigning a team. The ERP buying process starts with forming a project team led by a project manager and usually consisting of department heads, senior executives and IT.

- Defining requirements. The project team is charged with understanding the organization's current and aspirational ERP use cases, then gathering the requirements and wish lists of stakeholders.

- Researching vendors. The requirements planning stage provides the framework for researching ERP software vendors and asking the most promising ones to respond to a request for proposal (RFP) detailing how they will deliver the requirements. Some vendors can be called in to give sales presentations.

- Identifying the shortlist. The project team names a small group of vendors it believes is most likely to meet the requirements.

- Scheduling demos. The shortlisted vendors are called in to demonstrate how their software performs in real-world circumstances, sometimes in a competitive "bake-off."

- Selecting a vendor. After negotiating price and terms, the buyer signs a contract with the chosen vendor.

In practice, completing each major step requires several substeps and significant data collection. For example, requirements planning often involves surveys and meetings with users, or a formal gap analysis to determine whether the organization's business software meets current and future needs. Many organizations interview customers with similar needs and perform a financial analysis to assess the stability of shortlisted vendors.

The final choice usually comes down to how closely a product matches the buyer's required timeline, features, ease of use and price and whether it supports current or planned business processes. A product's deployment options can also tip the balance, besides heavily influencing the other criteria. A SaaS ERP product, for example, is more likely to fit a shorter implementation timeline and be easier to use than an on-premises system; but, as noted, it might lack the specialized functions a company needs to stay in business.

Buyers entering the market will find a few dozen ERP vendors that vary widely in size and target markets. There is specialized on-premises ERP for small law firms and giant chemical producers, basic cloud ERP for the project management and accounting of global consulting firms, and obscure brands of ERP sold mostly to regional manufacturers and distributors in the U.S.

Some ERP vendors, including Acumatica, NetSuite and Sage Intacct, specialize in the needs of SMBs, offering relatively affordable and simple ERP for common financial, order management and HR functions. Such entry-level products may be a company's first ERP system when it outgrows basic accounting software, but they can usually be expanded with additional modules and "scale," or grow, to accommodate more users and business functions.

Four major brand ERP vendors -- Infor, Microsoft, Oracle (including NetSuite) and SAP -- have the biggest market shares, with nearly half the worldwide total. These four also have the broadest product lines that span from entry-level ERP to complex software suites for multinational conglomerates, as well as specialized versions for most major industries. Some market researchers include Sage Intacct and Workday -- a fast-growing maker of SaaS HR and financial software -- among the market share leaders, but neither vendor has quite the breadth of products as the top four.

Other prominent ERP vendors include Epicor, IFS, Plex Systems, QAD, Syspro and Unit4.

ERP implementation

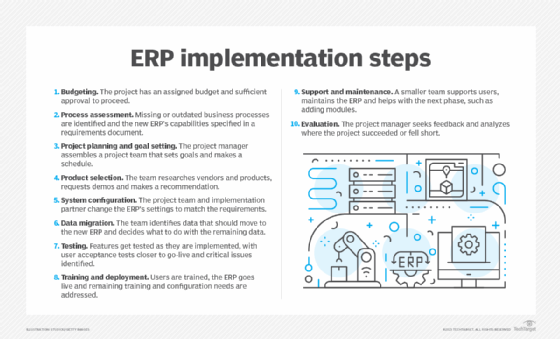

ERP implementation best practices call for a formal process, overseen by an ad hoc team drawn from every major department, that extends from the conceptual stage to post-implementation support and, ultimately, upgrading or replacing the system.

Project management methodologies and software are essential in managing what could be a multiyear process.

Often, a choice must be made between installing a new ERP system all at once or phasing in modules over time. Each approach comes with pluses and minuses. A "big bang" occurs in a single phase but typically is more expensive, while a phased approach tends to place less strain on resources but risks user dissatisfaction and integration hassles from keeping some of the old systems.

Once a vendor is chosen, the implementation begins. In the case of an ERP upgrade from one system to another, companies usually run and test the new ERP system in parallel with the old one to confirm that it works properly before committing to a launch date. Data migration then consumes much of the time and resources needed to ensure the new system can take over business processes with minimal disruption. However, careful budgeting and planning for all the major steps of the implementation process help ensure success (see Figure 4).

The best practices don't end when the system is deployed. Companies must communicate the benefits and features of the new system in advance, then maintain a training process for current and incoming employees. A comprehensive and effective change management strategy can be the difference between ERP implementation success and failure.

ERP support

The new system also has to be maintained. ERP vendors or their support partners offer tech support services, usually contracted for an additional fee. They typically include a help desk reachable by phone, email or online; a dedicated customer web portal with FAQs, user manuals and other documentation; and access to discussion forums. On-site support typically provides implementation assistance, troubleshooting and training.

Software development may be a significant part of support if the ERP system needs customizing, extending or integrating with other systems. It's one of the often unexpected costs of ERP, along with lost productivity, talent shortages, and integration and data management hassles, among others.

Most companies maintain their own ERP support staff, even if it is just one IT person who has other responsibilities. Larger companies may have several people whose job it is to keep the ERP system running, train users and interact with the ERP vendor, systems integrator or service provider. "ERP administrator" is a common title in the IT world.

The growing popularity of cloud ERP is bringing major changes to the internal ERP support function, which used to focus mostly on maintaining the ERP system itself. Now, ERP administrators must be knowledgeable about the capabilities of SaaS business applications, figure out how to assemble them into an ERP system and understand the needs of customers and other external users.

Why is ERP important?

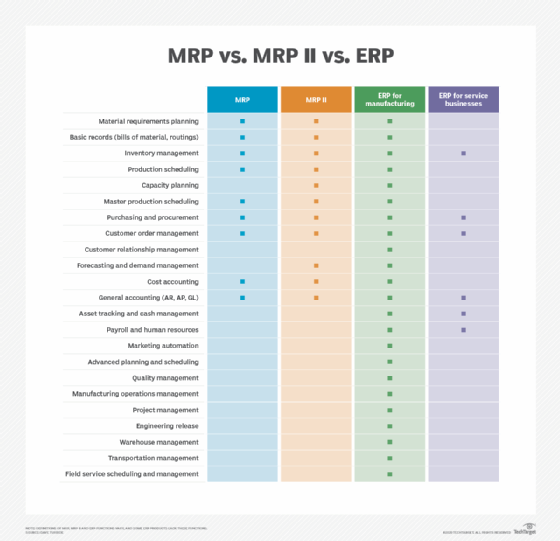

In one form or another, ERP has been at the center of efforts to exploit the data processing and calculating capacity of computers to manage complex business processes. This important software began as MRP, a system invented in the 1960s to plan the materials needed in manufacturing. The manufacturing planning system was later extended to other factors such as financials (see Figure 5), and was renamed manufacturing resource planning (MRP II).

When MRP II grew to encompass even more processes like payroll, HR and sales, the need for a generic term became clear; in 1990, ERP was coined. Today, MRP and ERP continue to play essential roles in manufacturing, and ERP has become the digital nervous system of business.

Few observers would doubt that ERP has also had a positive influence on the global economy. The anecdotal evidence from individual companies is both convincing and unsurprising, and it springs largely from the usual benefits of computerizing manual, paper-based processes.

Digitizing business transactions and records usually speeds them up and makes them more accurate and reliable. Sharing this real-time or near-real-time information over a network helps workers across departments make better decisions, coordinate their activities, collaborate more effectively and minimize the avoidable errors caused by miscommunication. It also helps businesses respond more quickly to changing conditions.

Tapping into the internet to open these ERP channels to the outside world helps to align supply and demand by tying the desires of customers more intimately to the actions a company, its suppliers and partners take to develop and deliver products and services.

This ongoing "digital transformation" of nearly every corner of the business world, enabled in large part by ERP, has made new conveniences, such as mobile e-commerce, possible. It has also helped to integrate the world economy by enabling -- or, at the very least, supporting -- global manufacturing, supply chain analytics and industrial IoT.

At the same time, digital transformation calls for a new set of ERP skills that emphasizes broad business expertise and collaboration to write the next chapter in the long partnership between ERP and business.

The future of ERP

In recent years, ERP vendors have bolstered their products with new technologies that are sweeping through other sectors of the IT industry. Today, the hottest ERP trends are all about making ERP more interactive, intuitive and "intelligent."

Artificial intelligence is having the biggest impact. AI improves ERP data analytics by "learning" to recognize patterns and make recommendations. Natural language processing (NLP) makes it possible to control ERP by speaking into a voice user interface. And AI-enabled chatbots are taking over many of the ERP tasks, such as invoice processing and customer service, formerly handled by humans.

The biggest recent driver of innovation in this more automated and interactive ERP is generative AI, a new type of machine learning that can mimic human communication and creativity. The instant popularity of ChatGPT when it came out in November 2022, and the emergence of a plethora of other generative AI tools, pushed ERP vendors to find as many ways as possible to embed generative AI in their products. Experts predict that generative AI's ability seemingly to understand a user's intentions will enable it to take on a much wider range of complex business processes in ERP when combined with more mature machine learning technology.

The cloud -- more precisely, SaaS -- is the platform for these AI developments and almost all the other innovations happening in ERP. It's the only deployment option with sufficient computing power and storage capacity to meet AI's huge data processing and computational needs and deliver the results on a mass scale.

SaaS plays another indispensable role in the evolution of ERP as the enabler of a new architectural model called composable ERP, in which SaaS modules from different vendors are pieced together to form a tailored suite of applications. Industry analysts have long predicted the arrival of this "postmodern," composable ERP. Vendors have recently begun delivering composable ERP products and tools such as cloud APIs to connect the components.

These developments point to a future ERP that will bear little resemblance to the clunky, character-based mainframe systems of the early days or the complex, massive ERP systems that took years to implement. Instead, the push is on to construct a mosaic of more responsive, human-centric, AI-powered applications. Ironically, the dismantling of the monolithic ERP systems that revolutionized business operations and helped spur a global economy might finally enable ERP to deliver on its promise to unify and automate businesses.

David Essex is an industry editor who covers enterprise applications, emerging technology and market trends, and creates in-depth content for several TechTarget websites.