Getty Images

Prepare a supply chain disaster recovery plan

Supply chain disruptions can bring business to a halt and lead to high costs. Examine potential threats, mitigation costs and prepare to plug any gaps in the chain.

One of the lasting outcomes of the COVID-19 pandemic is its ongoing impact on supply chains. Loss of personnel to handle transportation of goods, manage the logistics of goods movement and other issues has resulted in a growing and increasingly serious supply chain disaster in the U.S. Because of this, a comprehensive supply chain disaster recovery plan has become one of the top issues in business and government today.

Supply chain management (SCM) addresses the movement and storage of raw materials, work-in-process inventory and finished goods from the point of origin to point of consumption. It also encompasses the planning and management of all activities involved in sourcing, procurement, conversion and logistics management.

SCM includes the crucial components of coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers and customers. SCM integrates supply and demand management within and across companies.

Supply chain continuity and disaster recovery programs are key components of today's lean supply chains. Considering how much of a firm's survival rests on a strong and resilient supply chain, it's easy to see why supply chain continuity has become a strategic activity.

Below, you'll find a downloadable supply chain disaster recovery plan template to use as a framework. Customize these steps to craft a plan that fits the needs of any given organization.

Supply chain continuity and disaster recovery concepts

Supply chain continuity and disaster recovery take the concepts of traditional business continuity and disaster recovery (BCDR) and apply them to supply risk management. The goal is to guard against a major supply disruption that could potentially delay orders and result in loss of customers. A typical supply chain can include people, IT systems, communications, transportation, real estate and finance. Loss of or disruption to any of these elements can destroy the supply chain.

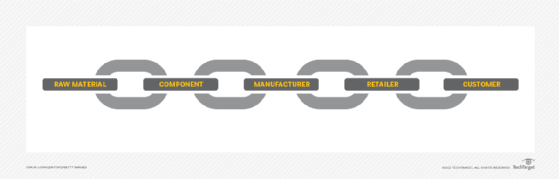

Figure 1 depicts a basic manufacturing supply chain, transitioning from raw materials to finished products that customers acquire.

Each two-way interface in the supply chain incorporates the following:

- the movement of goods;

- information flows;

- transfer of title; and

- purchase and sale.

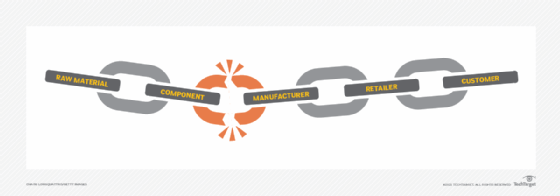

When all components and flows operate normally, finished products should get to consumers in an appropriate time frame. But what happens if something disrupts the supply chain, as depicted in Figure 2?

Suppose a distribution facility for a department store burns to the ground. What happens to the inventory? How is it replaced? How do shipments get delivered? These and many other questions must be addressed quickly if the department store will stay in business.

To be competitive and keep costs down, retailers and manufacturers have revised supply operations to tie investments closer to demand. But in doing this, it becomes harder to maintain a resilient supply chain, resulting in a potentially fragile supply chain. What can be done?

BCDR teams can perform several fundamental activities, including the following:

1) Perform a business impact analysis (BIA);

2) conduct a risk assessment;

3) develop disaster recovery and prevention strategies;

4) develop an IT DR plan;

5) conduct exercises testing the DR plan;

6) spread awareness of the plan and train staff;

7) maintain and update the plan over time; and

8) monitor and audit the DR plan for improvements.

Supply chain impact analysis

Perhaps the most important activity is the supply chain impact analysis. This involves gathering extensive data about all aspects of an organization's supply chain. Among the most important outcomes of this analysis is an understanding of the interdependencies among and between supply chain elements.

Without this knowledge, it is impossible to adequately identify mitigation strategies, respond to and repair the breaks, and return to normal operations as soon as possible. The process is similar to a BIA and attempts to gather data about the various supply chain relationships that exist. These relationships can focus on people, process and technology.

Supply chain risk assessment

A supply chain risk assessment helps identify internal and external threats to the chain's integrity, as well as vulnerabilities in the chain. The first step is to identify the most important supply chain impacts from the earlier analysis, how they affect the overall supply chain and the outcome if they were damaged.

Next, carefully identify and examine the threats and vulnerabilities that could disrupt or disable the most critical chain elements. Data from this analysis can help pinpoint opportunities to develop strategies, policies and plans that can directly address potential supply chain weak points.

Strategy development

Recalling the current process of lean supply chains, develop strategies that can cost-effectively address supply chain risk points. These might include using advanced supply chain management software, multiple manufacturing plants, multiple transportation firms and more. The challenge is to develop a composite strategy that addresses the broadest possible range of supply chain risks.

Plan development, exercising and maintenance

Develop process-level plans that map changes to the identified risks and strategies. Internal supply chain teams, selected vendors, technology organizations and key supply chain partners are all part of the plan development process. Their buy-in and ongoing support are critical if the plan is to succeed.

Once supply chain disaster recovery plans are developed, BCDR teams should run exercises until all parties in the supply chain agree as to how they will work together in an emergency. Awareness and training programs can spread the message to all employees, stakeholders and third-party organizations such as regulators and government agencies. Once the program is implemented, it's essential to schedule reviews, audits, additional exercises and updates for program maintenance.

To get started on planning for supply chain continuity and disaster recovery, download this template.