buchachon - Fotolia

A mechanical refrigeration system primer for admins

Mechanical cooling is a necessity to keep data centers efficient year-round. The system type you use depends on the refrigerant, number of heat exchanges and airflow requirements.

All the power for data center infrastructure becomes heat, which admins must efficiently remove to keep the hardware operational. A common cooling practice is to discharge the heat outdoors and use free cooling as much as possible.

In most facilities, mechanical refrigeration systems are still necessary to maintain data centers year-around. It's important to understand how mechanical cooling works to set the right conditions, minimize energy use, determine appropriate redundancies and maintain reliable systems.

Regardless of the systems admins use, it helps to understand cooling basics. Cooling depends on the following five principles:

- Heat must transfer to a medium that releases the heat someplace else. That requires fluid flow. Air, water and refrigerant are all considered fluid mediums that carry heat.

- Cooling of any kind requires airflow. Fans usually help accomplish this.

- Heat flows from the warmer to the cooler condition, so the temperature of the cooling medium must be higher than the medium to which the heat is transferred. The greater the temperature differential between the two mediums, known as "TD" or "Δ T," the more heat can be transferred. Refrigeration is simply a mechanical means of artificially creating higher temperature differentials.

- Refrigerants change state from liquid to gas, and back to liquid, at temperatures standard for data centers. Water can absorb more than 3,500 times the heat of air, so it is often used as a secondary medium but does not readily change state.

- Refrigerant fluid has a low boiling point, so equipment heat vaporizes the fluid. But the fluid is still not hot enough transfer heat to another medium like air or water. When a gas is compressed, its temperature goes up and its boiling or "vaporization" point goes down, as in a pressure cooker. The compressor is the heart of a mechanical refrigeration system.

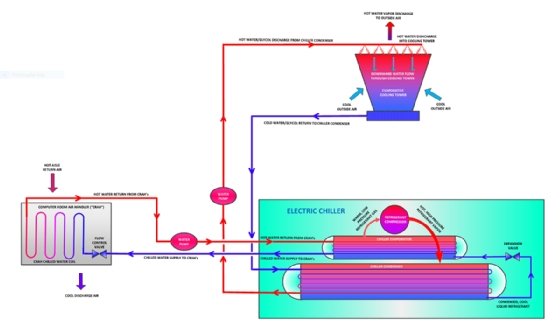

In any cooling process, there are several heat transfers. The simplest, air-side free cooling, transfers heat from inside air to cooler outside air. Water-side free cooling transfers heat from air to water, and back to air outside. These processes require only fan and/or pump energy.

When refrigerants are involved, there are more heat transfers. Mechanical refrigeration is simple in principle:

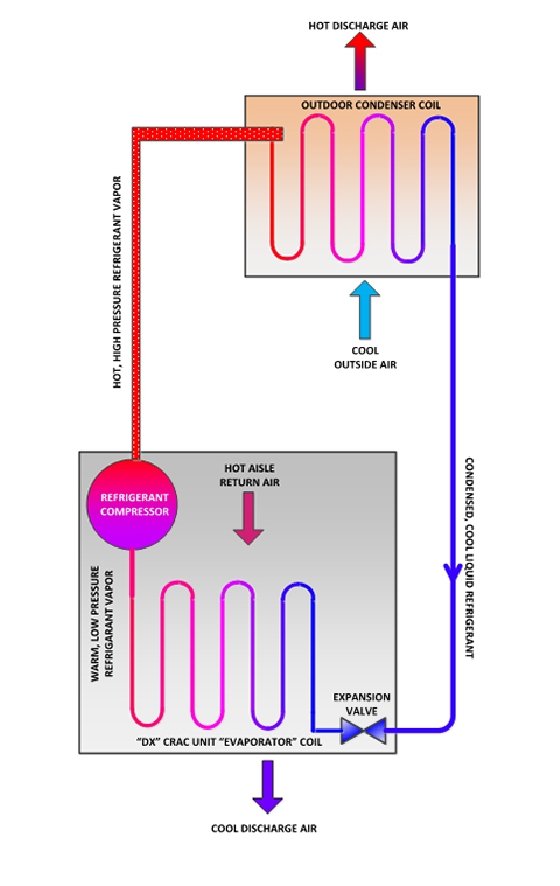

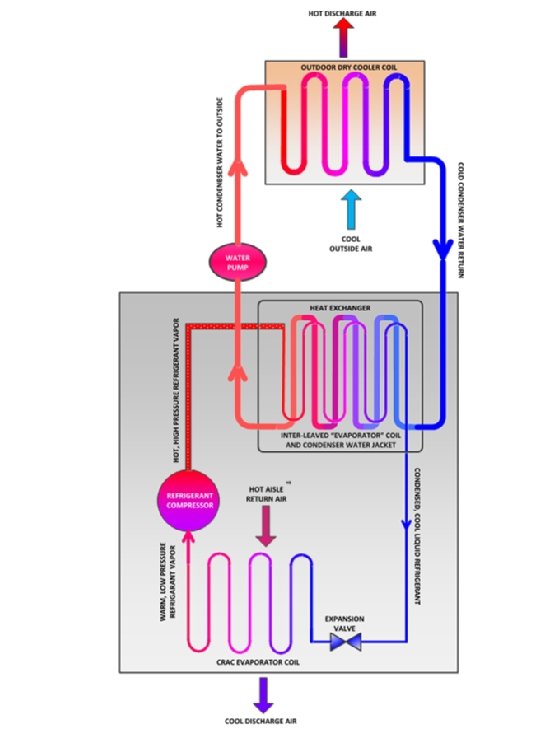

- Equipment heat is pulled through cooling coils, called evaporators, by fans. The heat boils the liquid refrigerant, converting it to warm gas. Fans discharge cool air back to the equipment.

- Expansion valves regulate the amount of refrigerant entering the cooling coils to match the heat our equipment produces, ensuring that all refrigerant in the coils is converted to gas. A faulty expansion valve, delivering too much refrigerant liquid, is inefficient.

- Compressors take in the warm, low-pressure refrigerant gas and increase its temperature while lowering its boiling point.

- Heat is carried outside, either by the hot refrigerant gas or through transfer to another medium, usually water.

Main mechanical refrigeration system types

Data centers use three fundamental types of mechanical refrigeration systems, each with a different number of heat exchanges. All use fans, pumps and a refrigeration loop with a compressor somewhere in the scheme. There are three main types of mechanical cooling systems.

Computer room air conditioners (CRACs) have built-in compressors. Computer room air handlers (CRAHs) are just coils and fans, with compressors -- called chillers -- somewhere else.

Compressors use lots of energy, so admins should run them efficiently and use them as little as possible. Data center CRACs and CRAHs are precision air conditioners, and control temperature within ±1 degree Fahrenheit and 4% relative humidity. They have a high sensible heat ratio, so admins must remove minimal moisture -- or latent heat -- and produce only sensible heat.

In a direct expansion system (Figure 1), equipment heat changes the refrigerant to warm, low-pressure gas. The compressor makes it hot, high-pressure gas, and a condenser transfers heat to outside air, then returns the gas to liquid. Refrigerant lines are limited in length, and each CRAC usually requires an individual condenser.

A water-glycol system (Figure 2), has the same initial process to heat up the refrigerant, but it circulates the compressed hot refrigerant gas through a water jacket heat exchanger that transfers the heat to a water loop.

The system then pumps water through a dry cooler that releases the heat to the outside air. The water returns and is pumped back through the heat exchanger at normal temperature to condense the refrigerant gas to liquid. Systems can pump water farther than refrigerant and can be used for multiple units.

Chilled-water CRAHs (Figure 3) use the largest compressors, known as chiller plants. These systems circulate refrigerant around internal water loops, where one loop sends chilled water to the CRAHs, and the other pumps hot water to outside cooling towers and have large fans cool the refrigerant through evaporation.

The greater temperature differential involved makes these mechanical refrigeration systems more efficient, despite the number of heat exchanges. Chilled water systems, however, are only practical in larger installations.

Maintenance best practices for mechanical refrigeration systems

To minimize energy use and maximize performance and reliability, admins must have appropriate cooling system design and good maintenance. Chillers require yearly maintenance and cooling towers require periodic descaling.

There are other best practices to consider. Keep filters clean to maximize airflow and remove airflow obstacles. Admins must also check refrigerant levels and ensure that the all-important expansion valve does not have any leaks.

Control units on discharge, rather than return air temperature, with remote sensors at appropriate cabinet intake points. Admins can run systems at higher temperature, within the ASHRAE thermal envelope, which saves energy and increases CRAC or CRAH capacity. Control humidity based on dew point, rather than relative humidity, per ASHRAE guidelines.

Simultaneously run redundant units, but at lower capacity, if possible. This is easy with CRAHs that use electronically commutated motors with variable frequency drives. This minimizes energy use and automatically maintains redundancy.