What is network management?

Network management is a multifaceted discipline that provides network administrators with the tools, protocols and processes to maintain and optimize network operations.

A computer network connects one machine, system or device to another. As a network grows from a handful of machines to hundreds or thousands of connected network devices, the complexity grows. Modern enterprise networks are no exception, and network teams must manage their networks effectively to support reliability for network resources, end users and business applications.

Network management encompasses several capabilities that help ensure ongoing network visibility, availability, performance and security. Key components of network management include the following:

- Network performance monitoring.

- Network monitoring.

- Network maintenance and troubleshooting.

- Network configuration management.

- Network provisioning.

- Network automation.

Why is network management important?

An important goal of network management is to improve reliability to minimize network disruptions and downtime. Network downtime affects revenue, employee productivity, reputation damage and Opex costs. Network admins use proactive network management methods to continuously monitor the network in real time and set up alerts for unusual activity. These methods include threat detection and patch management to address any security vulnerabilities.

Preventive maintenance -- such as scheduled updates, hardware upgrades and software updates -- helps network teams avoid unexpected failures and extend device lifecycles. Meanwhile, analytics and monitoring tools help network admins gather network data, identify bottlenecks, generate actionable reports and fix issues.

Ultimately, networks that operate with high performance and effective network security measures are more cost effective. Network management supports business objectives, enhances customer and user experience, optimizes resource usage, and enables scalability and future growth.

How does network management work?

The first step in network management is to collect information from the network. This information comes from network devices such as routers, switches and wireless access points. Software-based agents can also collect data from virtual or cloud services to provide visibility in network and application traffic flows.

Types of network devices

Explore some of the common networking devices used within enterprise network infrastructure, including access points, firewalls, gateways and routers.

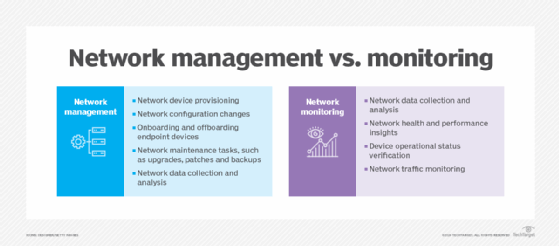

Network monitoring is a subset of network management and is essential for visibility into the network. Network teams typically implement network monitoring and analytics tools to collect device information and monitor performance, network traffic, bandwidth usage, faults and availability. These tools should be able to span on-premises, remote, cloud and hybrid infrastructures and work in both wired and wireless environments.

A number of protocols collect data useful for network management and establish rules of communication in the network. These protocols include the following:

- Simple Network Management Protocol. SNMP is commonly deployed on networking devices as a decades-old approach to obtain network information.

- Network Configuration Protocol. NETCONF is a protocol that provides mechanisms for network management tools and administrators to install, control and delete configuration data on connected network devices.

- RESTCONF. The RESTCONF protocol builds on top of NETCONF using a RESTful API-based approach to update and change network configuration.

- gNMI. The gRPC Network Management Interface (gNMI) protocol provides a way to obtain the given state for a network device or service. It also enables the ability to manipulate and modify the configuration for a device.

Most network teams opt to use a network management system (NMS) to help them manage the network infrastructure. NMSes integrate protocol support and provide capabilities to enable visibility into network flows for performance and availability monitoring. They also provide the ability to make policy and configuration changes to remediate issues and optimize operations.

Many modern network management and monitoring tools implement telemetry, AI and machine learning for real-time data collection, data analysis, traffic forecasting and anomaly detection.

Types of network management

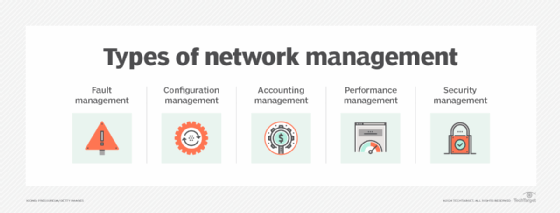

Network management is typically divided into five main categories, commonly known as the FCAPS framework:

- Fault management. Prioritizes the detection, repair and documentation of errors within the network.

- Configuration management. Addresses the setup, monitoring and documentation of any configuration changes within the network environment.

- Accounting management. Essential for tracking network usage, under- or overprovisioning, costs and billing.

- Performance management. Compiles network performance metrics and ensures the network meets quality-of-service levels.

- Security management. Focuses on network authentication, authorization, access controls and vulnerability management.

Altogether, these different categories focus on the major elements of network management. Each one outlines the proactive measures network administrators should take to identify potential problems and control the network.

Network management benefits

Network management provides several benefits to organizations and their users, including the following:

- Network visibility. Network monitoring provides a comprehensive, real-time view of the various devices, traffic flows and performance metrics within the network infrastructure. This visibility improves problem diagnosis, troubleshooting and compliance.

- Downtime detection. Downtime is a business-critical event for organizations. Network management tools can quickly detect network outages, identify the root cause and bring services back online. Reduced downtime minimizes business losses, customer dissatisfaction and employee disruptions.

- Performance optimization. Slow networks negatively affect business operations and goals. Network management optimizes performance by ensuring the network uses resources such as bandwidth, computing power and storage efficiently.

Network management challenges

Because of its inherent comprehensive nature, network management isn't always an easy task. Challenges include the following:

- Legacy networks. Organizations that rely on cumbersome legacy monitoring tools might find it difficult to manage disparate environments, such as virtual, hybrid and cloud-based networks. Legacy tools can also impede efforts to gain end-to-end visibility.

- Complexity and abstraction. Modern networks can also add complexity, as they're typically heterogeneous environments with different vendors, protocols, interfaces and tools. These environments are also hosted on-premises, in VMs and in cloud instances. While abstraction simplifies some of this complexity by using orchestration and automation, it can limit visibility into the network as well as granular control.

- Ephemeral IP addresses. Network admins typically use IP addresses to identify network devices and users. With virtualized and container-based applications, the use of ephemeral or elastic IP addresses can cause challenges in identifying users, applications and services.

- Interconnectivity. Even as multi-cloud environments grow more popular, the bridges that connect these environments can cause provisioning headaches, performance inconsistencies and security blind spots.

Best practices for managing networks

Network admins can follow an assortment of established tasks and best practices to ensure they manage their networks comprehensively.

Inventory the network

Audit the network and compile an accurate inventory of all devices and applications in it. Use tools that can discover devices automatically to spare IT the difficulty and tediousness of this task.

Reduce manual management

Network automation tools can be valuable assets in network management. While automation is a best practice, it's far too general a notion to implement wholesale. Instead, network admins should implement automation with simple and low-risk tasks to start.

For example, network teams can automate device locaters to do the following:

- Find out where a device connects to the network.

- Perform application connectivity checks.

- Verify that each network infrastructure device is properly connected to its neighbor.

- Find discrepancies between parts of network configurations and the organization's configuration templates.

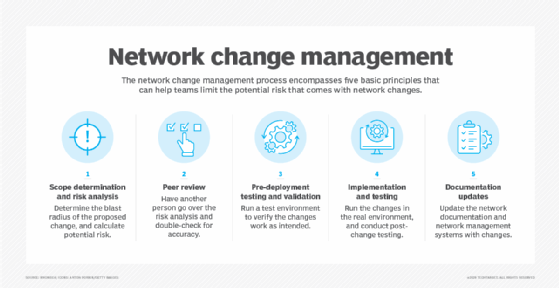

Evaluate the scope and risk of changes

Network change management is a vital process that reduces the risk of a failed change. Network admins can apply some basic operating principles to prevent potential missteps in the future. For example, consider the scope of a proposed change, such as determining how many endpoints might be affected by a change.

Network teams should pair scope evaluation with risk analysis. After that, they should put the change through peer reviews, pre-deployment testing and validation, implementation and testing, and documentation updates.

Document all processes

Documentation is useful in most areas of network management. It consolidates all information about the network in one location, thereby simplifying troubleshooting, enhancing security and compliance, and assisting with knowledge transfer.

Documentation should be regularly updated and include the following information:

- Network topology.

- Configuration.

- Standard operations procedures.

- Change logs.

- Access control records.

- Incident reports.

Cloud-based vs. on-premises network management

Network administrators can deploy network management in an on-premises or cloud-based model. Each model has its own benefits and challenges.

With on-premises systems, network admins install and operate the network management tools. A managed service provider might also handle on-premises deployments and remotely monitor and maintain an organization's network.

On-premises network management deployments can benefit from lower latency, in that the network being monitored is the same network that is being managed. Security can also potentially be stronger for an on-premises deployment, as the organization can tightly control and monitor access control.

With cloud-based approaches, network management is provided in a SaaS model. Cloud-based network management reduces the burden on an organization to set up and maintain its own on-premises network management deployment.

Cloud-based network management also offers potentially improved reliability, as it is provisioned and maintained on a separate network -- not the one it is monitoring. Cloud-based approaches can often provide better remote access for administration and are typically delivered in a subscription model.

Network management systems and capabilities

Many enterprises typically use multiple network management tools for various products and devices, despite vendor attempts to increase the interoperability and feature sets of their products. Most network management systems include the following capabilities, among others:

- Real-time status monitoring.

- Device discovery.

- Alerts and notifications.

- Event logging.

- Centralized management.

- Traffic analysis.

- Intrusion detection.

- Reporting and analytics.

- Multi-vendor support and third-party integration.

- Role-based access control.

- Automation, AI and machine learning.

AI, machine learning and automation streamline and automate many of the functions and tasks of network management, including provisioning, configuration and security. These tools expand visibility into the network infrastructure without increasing the burden on IT teams. They can also improve troubleshooting response times by discovering the root cause and implementing a fix.

Network management tools are evolving quickly as advanced technologies are built into them, leaving network teams to become more strategic in how they administer and manage their network environments.

Editor's note: This definition, originally written by Sean Michael Kerner, was updated and expanded by Jennifer English.

Sean Michael Kerner is an IT consultant, technology enthusiast and tinkerer. He has pulled Token Ring, configured NetWare and been known to compile his own Linux kernel. He consults with industry and media organizations on technology issues.

Jennifer English is executive editor for Informa TechTarget's Networking and Cloud sites. She joined Informa TechTarget as a writer and editor after graduating from the University of New Hampshire in 2016.