Use cases and benefits of smart sensors for IoT

Smart sensors are key to developing IoT applications, as they help modernize and streamline analytics and connectivity. Catch up on the types of IoT sensors, their use cases and more.

The internet of things couldn't exist without smart sensors.

While the use of sensor technology has long affected how manufacturers, industrial organizations and utilities operate, the addition of IoT to sensors has expanded their impact and use cases, bringing more connectivity and analytics to processes than ever before. Today, smart factories, smart cities, smart buildings and connected individuals are using an array of smart sensors to collect real-time data for real-time insights and decision-making.

However, these aren't your grandfather's sensors. They may collect some of the same data as the sensors of yesteryear, but today's smart sensors are internet-enabled and more sophisticated than ever.

Let's dive into how smart sensors work and their use cases across various verticals.

What is a smart sensor?

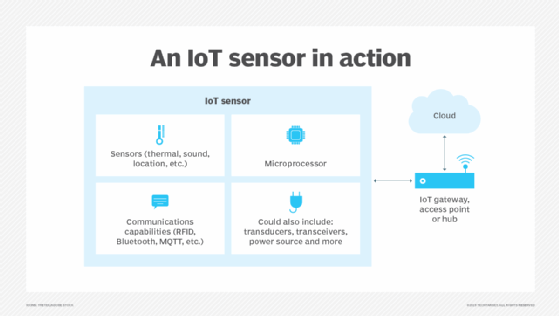

In general, a smart sensor has three major components: a sensor that captures data from an environment; a microprocessor, which computes on the output of the sensor via programming; and communications capabilities that enable the sensor to communicate the microprocessor's output for action.

A smart sensor may include multiple types of sensors (see sidebar), as well as transducers, transceivers, amplifiers, analog filters and a power source, among other components.

To be most effective, internet of things sensors should include wireless communications, be smart enough to compute data remotely and be programmable to accommodate new capabilities as needed, said Institute of Electrical and Electronics Engineers senior member Shawn Chandler.

Types of IoT sensors

"Sensors for use in IoT may be purposed for nearly any form of measurement, providing a mechanism that links desired observations from the field to an application," Chandler said.

To categorize sensors, he said, think of them in terms of the physics domains.

- Light and electromagnetism sensors. These include RFID sensors for retail and logistics applications, imaging and identity sensors for security applications, light sensors for automation in smart buildings, and radioactivity sensors for safety and health applications.

- Thermal sensors. For example, room temperature monitoring in smart buildings, environmental monitoring or material temperature monitoring in industrial process management.

- Vibration and sound sensors. For example, seismic sensors for regional safety; sound pressure for health monitoring and industrial process automation; specific sound monitoring for civil management applications, such as gunshot noise detection; personal health applications, such as fitness and health wearables; or vibration sensors for reliability-based maintenance of equipment in plants or for industrial organizations.

- Matter and materials sensors. Many applications for environmental, safety, health, agricultural and environmental automation require specific fluid and gas sensors, such as those to detect a chemical presence or oxygen, carbon dioxide, humidity or water levels.

- Time and space sensors. For example, Geographic Information System location sensors for logistics management; personal applications; or location, velocity and acceleration sensors for vehicle and traffic management.

IoT sensor use cases

Smart sensors serve three broad purposes. First, they provide greater visibility into existing processes and workflows, identifying items, locating them and determining their environmental conditions. For example, smart sensors in industrial IoT environments can keep track of temperature and humidity, can log data for historical records and quality management, or can be used as triggers for alarms or process management in plants or warehouses.

Second, IoT sensors can be embedded into products to improve processes or the products themselves. In the manufacturing process, sensors can monitor, control and improve operations or be added to logistics to streamline how products are delivered. When embedded in devices, smart products can create new revenue possibilities.

Third, the lower cost and more advanced capabilities of sensors enable wider and more effective use cases. The cost of physical sensors and RFID tags has dropped considerably, as have the costs of smart sensor software applications, connectivity options and deployments.

Smart sensor benefits

The three use cases of IoT sensors outlined above lead to three categories of benefits, said Paul Miller, a senior analyst at Forrester Research.

First, the increased visibility IoT sensors provide into existing workflows and processes enable companies to see where things are thanks to real-time data. For example, logistics companies can outfit their fleet of vehicles with sensors to detect the location of each truck.

As companies begin to mine data from those sensors, Miller said, the second benefit emerges: predicting what comes next. In the same logistics example, collecting real-time data about where a fleet has been and how long trucks take to complete their routes can enable the company to predict when drivers will deliver packages. Smart sensors in logistics can also gather information about a driver's driving style and the size and weight of packages, as well as external data, such as traffic or weather conditions that may affect delivery.

"Now you build a rich and, hopefully, accurate model that can be used to improve communication with customers, optimize loading and routing, or reduce costs and emissions," Miller said.

In another example, smart sensors in manufacturing can collect historical machine data that companies can use to build models to predict when machine components are likely to fail.

"Instead of facing the potentially huge cost of unplanned downtime for a production line or factory, suspect components can be proactively replaced during scheduled periods of time," Miller said.

The third benefit of smart sensors relates to revenue generation; IoT creates a number of new business models. With data about how a machine operates, how it is used and how it wears out, manufacturers can offer outcome-based services to customers, Miller said. Manufacturers can now include consumables, servicing and even replacement parts in the price of a machine.

"Companies like Kaeser Compressor in Germany, which traditionally made and sold compressed air machines, are now able to offer compressed air as a service and charge customers by the liter of compressed air consumed," Miller said. "Consumables, spare parts, servicing and even the machine itself are only paid for when they're needed and used."

RFID and IoT

RFID tags are IoT sensors that collect data about the specific object to which a tag is attached. Commonly used in supply chain management, ID badging and access control, RFID tagging involves sending data using specific radio wave emissions.

RFID has two forms, Chandler said: active and passive. An active RFID tag contains an onboard power supply, enabling a tag to communicate data at any time and over larger distances. A passive RFID tag may not communicate unless it is activated by a radio frequency emission. It then uses the radio wave captured by the antenna in the tag to activate data collection and power the return communication path.

The future of smart sensors

Forrester Research predicts that smart sensor-based, track-and-trace and smart products will be the fastest-growing use cases, with 24.2% and 24% compound annual growth rates respectively. But the applications won't stop there.

"Sensors are increasingly being built into products at the point of manufacture," Miller said. "Industrial equipment, trains, planes and buildings increasingly arrive with hundreds or even thousands of sensors already connected."

However, internet of things sensors aren't limited to only new products.

"In markets like industrial manufacturing, where machines may have a life span measured in decades, there's also a healthy market in retrofitting sensors to older equipment," Miller said, noting that lowered sensor costs combined with the growing prevalence of infrastructure that can support IoT data flows will result in companies deploying sensors in greater numbers.

"Where today, a logistics company might install sensors in a truck, tomorrow it may be cost-effective to install sensors in every pallet or even every package," Miller said.

The arrival of 5G, he added, will eventually make it easier to work with a large number of sensors, even in environments where data latency causes problems today.

Also of note is the increased use of edge computing. As more analytics, including the use of machine learning and artificial intelligence, is run at the point of data collection, organizations -- or the sensors themselves or the IoT edge gateways the sensors connect to -- will be able to make decisions faster and more effectively.

Chandler noted that the continued miniaturization of sensors will change the future sensor landscape.

"Sensors will continue to get smaller over time and more capable in terms of computational capability," he said.

Sensors will also offer more functions in the same platform, serving different sensing categories from the same devices.

"Sensors will be installed in more and more devices, with everything from wearables to special-purpose sensors linking observations from our environment to a computing platform," Chandler said. "Estimates from pundits in the industry expect that the total number of IoT devices -- and, thus, possible sensors -- will triple in the next six years, with roughly 25 billion devices today, growing to 75 billion devices in 2025."

Additional reporting by Jim O'Donnell.